OzzyO

Western Thunderer

Hello all,

I'm having a short break from building the PoS while I get some parts namely ETH gear and the communication gear for the end of the coach. So, I thought that I'd make a start on Ian's JLTRT, BG.

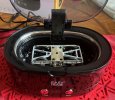

What's in the box as a start the resin parts, I'll photo the other castings as I have to open the bags.

So, from the top, the floor pan, roof, body sides, to the right body ends and part of the guard's compartment.

The etches, I'm a bit surprised that no window guard rail are on the etch like in the PoS kit.

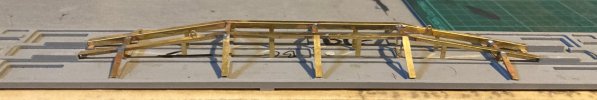

I started with the angle trusses and had the same problem with folding them as on the PoS. The brass is a bit thick at 18 thou but with a half-etched line and then scoring them it was out with the hammers again.

After the bending? I got this.

After I got it something like straight and flat it was onto some assembly.

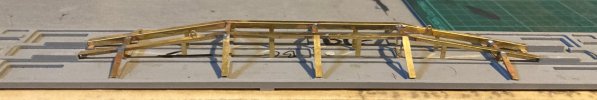

Then fitting it to the floor pan, to get this.

A close up showing some of the bits that need a bit of work. I'm thing about adding some pins (or bits of brass wire) down the backs of the uprights to add more support for the truss.

It looks like I don't have to add the bottom lip of the solebar on the BG as what I can work out from photos it looks like the solebars were flat faced.

ATB

OzzyO.

I'm having a short break from building the PoS while I get some parts namely ETH gear and the communication gear for the end of the coach. So, I thought that I'd make a start on Ian's JLTRT, BG.

What's in the box as a start the resin parts, I'll photo the other castings as I have to open the bags.

So, from the top, the floor pan, roof, body sides, to the right body ends and part of the guard's compartment.

The etches, I'm a bit surprised that no window guard rail are on the etch like in the PoS kit.

I started with the angle trusses and had the same problem with folding them as on the PoS. The brass is a bit thick at 18 thou but with a half-etched line and then scoring them it was out with the hammers again.

After the bending? I got this.

After I got it something like straight and flat it was onto some assembly.

Then fitting it to the floor pan, to get this.

A close up showing some of the bits that need a bit of work. I'm thing about adding some pins (or bits of brass wire) down the backs of the uprights to add more support for the truss.

It looks like I don't have to add the bottom lip of the solebar on the BG as what I can work out from photos it looks like the solebars were flat faced.

ATB

OzzyO.