You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Mickoo's Commercial Workbench

- Thread starter mickoo

- Start date

mickoo

Western Thunderer

Problem is, the gearbox is so big you essentially end up with just two sides and a front, no floor past the first say 10 mm. There will be no light through the side as the gearbox shows though. I'll do a couple of demo shots later today.Personally, I would make the firebox accurate and, if you have to use the gearbox, cut out a slot big enough for it and blacken the box and the final gear. Then at least there could be some light visible when looked through from the side. I agree, not ideal though.

mickoo

Western Thunderer

It's just standard grey resin sprayed red oxide, much easier to see the details and what's been added, more for visuals than anything else really.Mick,

What's the Red Oxide resin you are using for your prints?

Rob

Rob R

Western Thunderer

It's just standard grey resin sprayed red oxide, much easier to see the details and what's been added, more for visuals than anything else really.

Ahhh, I thought you had found something fancy!

Thanks

Rob

mickoo

Western Thunderer

You can do, people often mix colours or even resins, I prefer grey and the reliability of a single resin, I don't really have time to experiment or finances for the resultant waste during such exercises. Besides, default grey does everything I need it to do.Ahhh, I thought you had found something fancy!

Thanks

Rob

mickoo

Western Thunderer

Well that was an interesting exercise.

Kit ash pan side which sweeps up over the rear axle.....sort of, you can see the gearbox, and gears through the rear wheel, just I will concede that.

Modified full length ash pan side, it blocks the gearbox except for the large final gear on the axle.

Original kit ash pan side which sweeps up to reveal gearbox and gears.

Modified ash pan side covering all but final gear.

These are probably the more telling views, the ash pan floor. First up the floor as it would be with the kit sides and sweeping up over the rear axle, essentially a small strip at the front with two fingers sweeping up the sides toward the rear axle. A new section at the back where the rear damper is can be added but is not in the kit.

The ash pan floor on the revised model, enclosing all but the final gear, even then I may add a couple of shaped sides and cover to completely enclose the gear. New rear end damper already designed into the side piece.

If I mounted the motor the other way I.E. horizontal with vertical gear box, then the up swept area would be more clear of gearbox, you'd still have to contend with that massive final gear in view though, there is no getting away from that. The gear box would then also have an impact on the rear damper area as it cuts into that space a bit. I may also have to do other surgical work on the motor tail end or cab area if the gearbox is mounted in a vertical plane.

At the end of the day we're never going to win

Kit ash pan side which sweeps up over the rear axle.....sort of, you can see the gearbox, and gears through the rear wheel, just I will concede that.

Modified full length ash pan side, it blocks the gearbox except for the large final gear on the axle.

Original kit ash pan side which sweeps up to reveal gearbox and gears.

Modified ash pan side covering all but final gear.

These are probably the more telling views, the ash pan floor. First up the floor as it would be with the kit sides and sweeping up over the rear axle, essentially a small strip at the front with two fingers sweeping up the sides toward the rear axle. A new section at the back where the rear damper is can be added but is not in the kit.

The ash pan floor on the revised model, enclosing all but the final gear, even then I may add a couple of shaped sides and cover to completely enclose the gear. New rear end damper already designed into the side piece.

If I mounted the motor the other way I.E. horizontal with vertical gear box, then the up swept area would be more clear of gearbox, you'd still have to contend with that massive final gear in view though, there is no getting away from that. The gear box would then also have an impact on the rear damper area as it cuts into that space a bit. I may also have to do other surgical work on the motor tail end or cab area if the gearbox is mounted in a vertical plane.

At the end of the day we're never going to win

Last edited:

mickoo

Western Thunderer

mickoo

Western Thunderer

No problems, I needed some practice with the crayonsSorry, thought the brass bit underneath was the side of the gearbox..

JB.

Scale7JB

Western Thunderer

Seeing that axle protruding through the ash pan reminds me of what a nightmare it is to prep Pitchford hall of a morning.

Cleaning out two ash pans (either side of the axle) of the previous days ash through 4 damper doors, and then oiling up the rear underkeeps next to two of the slightly bent damper doors whilst it’s raining hot rocks down on you. Set fire to myself on a couple of occasions!

JB.

Cleaning out two ash pans (either side of the axle) of the previous days ash through 4 damper doors, and then oiling up the rear underkeeps next to two of the slightly bent damper doors whilst it’s raining hot rocks down on you. Set fire to myself on a couple of occasions!

JB.

AJC

Western Thunderer

Seeing that axle protruding through the ash pan reminds me of what a nightmare it is to prep Pitchford hall of a morning.

Cleaning out two ash pans (either side of the axle) of the previous days ash through 4 damper doors, and then oiling up the rear underkeeps next to two of the slightly bent damper doors whilst it’s raining hot rocks down on you. Set fire to myself on a couple of occasions!

JB.

Could be worse, JB - imagine oiling round or raking out on any of Swindon's designs without a pit.. (as dad did at Ashburton and Buckfastleigh in the early days).

Adam

Dave Holt

Western Thunderer

Perhaps a compromise profile for the ash pan sides could follow the prototypical upward slope to a point just above the lower edge of the frame plate and then project back down to cover the gearbox sides? That way, it would have the correct side profile between the driving wheels, where it is most visible.

Dave.

Dave.

Scale7JB

Western Thunderer

Funny you should say that, the above stories were from the early days when we didn’t have a pit either. I had to pull myself through the wheels and brake rigging with about 200lb on the gauge. Needless to say I spent as little time in there as possible!Could be worse, JB - imagine oiling round or raking out on any of Swindon's designs without a pit.. (as dad did at Ashburton and Buckfastleigh in the early days).

Adam

Normally most firemen would jump at the chance of oiling up but on those occasions the call of “can you oil up underneath for us..” was done with a small dose of fear.

JB.

mickoo

Western Thunderer

You could, problem is the gear box is massive and full length slab sides hang below the frames for the full length, the alternative new full length sides do just cover it with minimal clearance. I'll post a photo up later that might show it better.Perhaps a compromise profile for the ash pan sides could follow the prototypical upward slope to a point just above the lower edge of the frame plate and then project back down to cover the gearbox sides? That way, it would have the correct side profile between the driving wheels, where it is most visible.

Dave.

mickoo

Western Thunderer

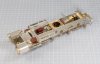

As promised some photos with the gearbox in place.

Kit ash pan side in nickel silver, there's about 1 mm clearance between that and the gear box side so the floor is very short and even if you then changed the rear profile to match the gear box sides the intermediate gear will poke through, let alone the final axle one.

The kit is clearly designed to drive the middle axle; in that case you could easily build a full ash pan with up swept floor and rear damper, but, you would have no middle stays, reservoirs or pipe runs and the gear box would show through the rear of the two circular lightening holes.

Revised ash pan side, you could possibly sweep it up a few mm and still cover the intermediate gear, but what you have is already wrong and what you end up with will also be wrong, so which wrong is right? I simply extended the base flat all the way through because I (currently) think that's the better right of all the wrongs available.

Even with the revised profile the final gear will poke through, a simple small separate cover on top should hide that. The small flat base at the rear could/needs (and probably will be) to be raised a few mm as it currently makes the rear damper too deep when viewed through the rear circular lightening hole.

Whatever orientation or motor you choose with the VML2 gearbox then that final gear is going to be visible.

By end of play today, one of these sides will be fitted as it's soon going to be holding up progress.

In other news, I did manage to get the reservoirs piped up and the retention straps fitted, doing one was a witch, the second to match an exercise to test even the calmest Buddha. I need to add two pipe clips to the run along the inside of the frame and then do the same on the other side, though that pipe eventually goes back to the cab.

Kit ash pan side in nickel silver, there's about 1 mm clearance between that and the gear box side so the floor is very short and even if you then changed the rear profile to match the gear box sides the intermediate gear will poke through, let alone the final axle one.

The kit is clearly designed to drive the middle axle; in that case you could easily build a full ash pan with up swept floor and rear damper, but, you would have no middle stays, reservoirs or pipe runs and the gear box would show through the rear of the two circular lightening holes.

Revised ash pan side, you could possibly sweep it up a few mm and still cover the intermediate gear, but what you have is already wrong and what you end up with will also be wrong, so which wrong is right? I simply extended the base flat all the way through because I (currently) think that's the better right of all the wrongs available.

Even with the revised profile the final gear will poke through, a simple small separate cover on top should hide that. The small flat base at the rear could/needs (and probably will be) to be raised a few mm as it currently makes the rear damper too deep when viewed through the rear circular lightening hole.

Whatever orientation or motor you choose with the VML2 gearbox then that final gear is going to be visible.

By end of play today, one of these sides will be fitted as it's soon going to be holding up progress.

In other news, I did manage to get the reservoirs piped up and the retention straps fitted, doing one was a witch, the second to match an exercise to test even the calmest Buddha. I need to add two pipe clips to the run along the inside of the frame and then do the same on the other side, though that pipe eventually goes back to the cab.

Last edited:

mickoo

Western Thunderer

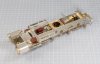

More MOK King Arthur progress.

The ash pan front is now all done, installed and connected up, firebox front too, the ash pan rear is in the printer and once fitted then the base can go on. That paves the way for the steam cock linkages and vacuum pipe to complete toward the rear injectors. Once all that is done then the brakes and pull rods can finally be fitted.

Rear steps and draw bar beam assembly is only in temporarily for the photos, it'll be easier to pipe up most of the injectors with it removed I think. I couldn't find and draw bar rubbing plate casting in the instructions or parts bags so whizzed one up in 3D, it's only cosmetic and so long as it does not hit the tender should be just fine.

I may as yet still add the three oil lines to the leading horn guides as they may just be visible top side up. There should also be three on the intermediate horn guides but top view is blocked by the flat plate and underside view blocked by just about everything really.

The ash pan front is now all done, installed and connected up, firebox front too, the ash pan rear is in the printer and once fitted then the base can go on. That paves the way for the steam cock linkages and vacuum pipe to complete toward the rear injectors. Once all that is done then the brakes and pull rods can finally be fitted.

Rear steps and draw bar beam assembly is only in temporarily for the photos, it'll be easier to pipe up most of the injectors with it removed I think. I couldn't find and draw bar rubbing plate casting in the instructions or parts bags so whizzed one up in 3D, it's only cosmetic and so long as it does not hit the tender should be just fine.

I may as yet still add the three oil lines to the leading horn guides as they may just be visible top side up. There should also be three on the intermediate horn guides but top view is blocked by the flat plate and underside view blocked by just about everything really.

Eastsidepilot

Western Thunderer

Chemically blacken the sides of the large steel gear wheel and you'll never notice it on the layout, but someone like me might notice the gauge

Great build as always mate

Col.

Great build as always mate

Col.

mickoo

Western Thunderer

Another week, another update.

Pretty much all the new linkages and pipework (not under cab yet) are in, just the two outside steam cock ones to fabricate and cranks to suit down by the cylinder rear face.

New splashers for the bogie rear wheels (not in the kit), sand boxes in the bin, too small and heavy cooling shrinkage, they were also designed to attach to the massive flange on the motion bracket, that went too; now we have a front end a bit more prototypical. Added brake linkage safety strap (handy as it also doubles as the sanding pipe fixing bracket), ash pan floor and rear 3D damper.

Pretty much all the new linkages and pipework (not under cab yet) are in, just the two outside steam cock ones to fabricate and cranks to suit down by the cylinder rear face.

New splashers for the bogie rear wheels (not in the kit), sand boxes in the bin, too small and heavy cooling shrinkage, they were also designed to attach to the massive flange on the motion bracket, that went too; now we have a front end a bit more prototypical. Added brake linkage safety strap (handy as it also doubles as the sanding pipe fixing bracket), ash pan floor and rear 3D damper.