You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help required producing unusual buffers.

- Thread starter John Duffy

- Start date

Overseer

Western Thunderer

I thought the buffer had three fins when I saw the first photo as the upper fin appears vertical while the side one is at an angle rather than horizontal, but I am not sure. Is the top fin wider to form a step?Looking closely at some of the feedback and info that has been supplied I am now questioning the number of fins. The Tatlow drawing shows top and bottom plus left and right but the images don’t seem to bear this out. There is not a horizontal fin showing.

I am now wondering if there were 3 fins rather than 4.

Any thoughts?

These would be quite easy to fabricate from brass tube with a ring of wire soldered to the outer end. The fins could be added with pieces of brass or styrene sheet.

Mike Trice

Western Thunderer

To me it looks like 4 with the fins being at 1:30, 4:30, 7:30 and 10:30 rather than 12:00, 3:00, 6:00 and 9:00.

John Duffy

Western Thunderer

Looking the part Simon. I think the suggestion about the fins in the diagonal corners must be correct.Top two & fourth pix in Rob's post suggest 4 at 45 degrees

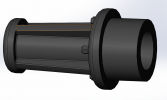

how's this?

View attachment 185077

View attachment 185078

the hole in the middle is wrong but I can soon fix that to suit the shank of the buffer

thoughts?

atb

Simon

John

90 degrees?Top two & fourth pix in Rob's post suggest 4 at 45 degrees

how's this?

View attachment 185077

View attachment 185078

the hole in the middle is wrong but I can soon fix that to suit the shank of the buffer

thoughts?

atb

Simon

AndyB

Western Thunderer

<OCD mode>

Given the age of the wagon, would it not have pre-war sized nuts? These look a bit as though they are on wartime rations!

Assuming they are 3/4" bolts, the nuts should be 1.3" A/F

</OCD mode>

simond

Western Thunderer

Well, to one another, yes, but 45 degrees to horizontal or vertical.90 degrees?

AndyB

Western Thunderer

Is the PCD of the bolts taken from a drawing dimension? If not, it looks like it could increase by 1/4".Andy, the nuts are smaller, the washers are 7/8” dia. Bigger wouldn’t fit…

Washers were not generally needed when the nut was engaging on a casting (only onto timber). One of the best pictures showing this (that I have) is in Tatlow vol.1 page 27, which clearly shows there to be no washer on any of the buffer bolts. This is on a GN / CLC wagon, but I think that most pre-grouping wagons would have been the same in this respect.

No socket wrenches or ring spanners used then, so sometimes they were placed fairly close to an adjacent face (true also of some tractors built in the 50's & 60's!)

Andy

Brian McKenzie

Western Thunderer

3 fins would be inconvenient to cast, whereas 4 fins make for an easier life for both patternmaker and foundryman.I am now wondering if there were 3 fins rather than 4.

Any thoughts?

Phil O

Western Thunderer

<OCD mode>

Given the age of the wagon, would it not have pre-war sized nuts? These look a bit as though they are on wartime rations!

Assuming they are 3/4" bolts, the nuts should be 1.3" A/F

</OCD mode>

They are more likely to be Whitworth which will be bigger than A/F nuts and bolts.

Overseer

Western Thunderer

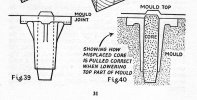

Only if cast horizontally. The ring on the outer end of the buffer stock was usually a separate wrought iron piece shrunk on after casting to add strength. It is just as easy to cast 3 fins as 4 with the cavity vertical in the sand. 3 fin/rib buffers were quite common, as were buffers with the ribs at odd angles.3 fins would be inconvenient to cast, whereas 4 fins make for an easier life for both patternmaker and foundryman.

These are circa 1860 3 rib buffers (note 3 bolts) made by Bray Waddington in Leeds.

EDIT: to add a drawing from Patternmaking by LL Cox, Pitman 1952, showing a similar buffer type shape set up to be cast vertically.

Last edited:

Pencarrow

Western Thunderer

Only if cast horizontally. The ring on the outer end of the buffer stock was usually a separate wrought iron piece shrunk on after casting to add strength. It is just as easy to cast 3 fins as 4 with the cavity vertical in the sand. 3 fin/rib buffers were quite common, as were buffers with the ribs at odd angles.

These are circa 1860 3 rib buffers (note 3 bolts) made by Bray Waddington in Leeds.

View attachment 185107

EDIT: to add a drawing from Patternmaking by LL Cox, Pitman 1952, showing a similar buffer type shape set up to be cast vertically.

View attachment 185108

Interesting photo but am I seeing things? Are the two buffer stocks orientated differently by c45deg??

Osgood

Western Thunderer

Notwithstanding a day full of hassle, this has been bugging me all day.

Although one would expect both the 3 x bolt holes and 3 x webs to be spaced at 120 deg., I'm certain that either bolts or webs - or both - are not equi-spaced.

Not only that - I have a suspicion the two castings are right and left-handed.

Although one would expect both the 3 x bolt holes and 3 x webs to be spaced at 120 deg., I'm certain that either bolts or webs - or both - are not equi-spaced.

Not only that - I have a suspicion the two castings are right and left-handed.

Last edited:

simond

Western Thunderer

I could imagine that the fins are 120 degrees with two or three bolt holes - one fin horizontal and the bolt holes top & bottom, but I can’t convince myself about the existence, or not, of the third fixing, which may, or may not, be opposite the horizontal fin.

either way the same casting would work in all four corners.

are these the same as the ones I have attempted to model?

If so, the orientation is reversed, the bolster does not have a horizontal fin on the outside, whereas the vehicle (it’s gloss - coaching stock?) in Fraser’s post does.

either way the same casting would work in all four corners.

are these the same as the ones I have attempted to model?

If so, the orientation is reversed, the bolster does not have a horizontal fin on the outside, whereas the vehicle (it’s gloss - coaching stock?) in Fraser’s post does.

Last edited: