P A D

Western Thunderer

Hello, having recently completed building the Gladiator 7mm Duchess and written it up on RMWeb, I thought I would do an abridged version on here, to compare and contrast with Richard Lambert’s superb Finney 7 build, and the resurrection job that Roger Scanlon did on the ready built one that he purchased.

Having read Richard’s build and seen the model in the flesh at Leigh and Doncaster, I just had to have a Duchess. However, the F7 kit is beyond my budget so I decided to see what I could make of the Gladiator version. Before I bought it, I was aware that there was an issue with the width of the cast resin firebox. I spoke to David Hill on the phone and he was quite open and frank about it, and then having inspected the kit at Doncaster, was happy that I could solve the problem.

As you can see from this photo the diameter of the joint at the front of the firebox does not match the brass boiler tube which is correct.

After making various checks and measurements, I decided that it needed widening by about 1.5mm. To do this I cut it down the centre line on the top and added a T shaped insert of 60 thou plastic card, fixed with epoxy.

This gave an improved fit, but the ring on the front was still a little small. This was widened by dipping the front of the casting in a pan of boiling water, then gently spreading with a suitable length of wood, and cooling in cold water.

The rivet detail on the firebox was also on the heavy side as can be seen in the last photo, so I removed them all and replaced with Scale Hardware items. Much better.

It was also clear that the firebox was not tall enough so a further insert was needed at the bottom to raise it up. This also served the purpose of providing a point where a bolt could be used to screw the casting to the running plate. For a more secure fitting, I also added a plate to the gap at the rear which is then bolted to the cab front. This then meant that I could make the smokebox, boiler and firebox as one detachable unit. I experimented with 40,60 and 80 thou plastic card and settled on 40 thou. That’s the 80 on top and the 40 below.

And after cutting an aperture for the motor and gluing in place with epoxy. It was made slightly wider than the box to represent the flange at the bottom, which I filed off before fitting the base.

Here’s a view inside the box showing the brass plate with 8 BA nut glued to the rear plate (80thou plastic card).

And from the rear. I had to add a further layer of 20 thou plastic card as their was a gap at the top. The thin brass sheet allowed me to solder thin strips of brass either side to replace the vertical beading which was very prone to damage.

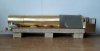

Here’s the boiler glued to the firebox. Further plastic card packing was needed to fill the gap created over the rear splasher by raising the box.

Here’s how it bolts to the running plate and cab front. Whilst I’ve been building the kit I’ve left off the bolts and nuts through the running plate as it’s very rigid withou them. I’ll put them back after painting to get a tight fit.

And in place later in the build.

Another error is the length of the smokebox, which is 2mm too long. Fortunately the extra length is at the rear behind the back row of rivets so is easy to rectify. If you don’t cut this back then the smokebox overhangs the front of the large steam pipe casting when it should be flush. I’ve seen a number of these on various websites with the smokebox overhanging. I’m not sure but I think this affects the David Andrews kit also.

The panel lines at the front were scribed on and the rivets added (Scale Hardware). In fact I think these are screws on the prototype as are the ones on the firebox cladding.

Once the firebox was sorted out, everything else was pretty much as per the kit instructions. One further mod I made to the boiler, was to make a representation of the front support bracket. I’ve not seen it on model before so maybe it’s a first?

Having read Richard’s build and seen the model in the flesh at Leigh and Doncaster, I just had to have a Duchess. However, the F7 kit is beyond my budget so I decided to see what I could make of the Gladiator version. Before I bought it, I was aware that there was an issue with the width of the cast resin firebox. I spoke to David Hill on the phone and he was quite open and frank about it, and then having inspected the kit at Doncaster, was happy that I could solve the problem.

As you can see from this photo the diameter of the joint at the front of the firebox does not match the brass boiler tube which is correct.

After making various checks and measurements, I decided that it needed widening by about 1.5mm. To do this I cut it down the centre line on the top and added a T shaped insert of 60 thou plastic card, fixed with epoxy.

This gave an improved fit, but the ring on the front was still a little small. This was widened by dipping the front of the casting in a pan of boiling water, then gently spreading with a suitable length of wood, and cooling in cold water.

The rivet detail on the firebox was also on the heavy side as can be seen in the last photo, so I removed them all and replaced with Scale Hardware items. Much better.

It was also clear that the firebox was not tall enough so a further insert was needed at the bottom to raise it up. This also served the purpose of providing a point where a bolt could be used to screw the casting to the running plate. For a more secure fitting, I also added a plate to the gap at the rear which is then bolted to the cab front. This then meant that I could make the smokebox, boiler and firebox as one detachable unit. I experimented with 40,60 and 80 thou plastic card and settled on 40 thou. That’s the 80 on top and the 40 below.

And after cutting an aperture for the motor and gluing in place with epoxy. It was made slightly wider than the box to represent the flange at the bottom, which I filed off before fitting the base.

Here’s a view inside the box showing the brass plate with 8 BA nut glued to the rear plate (80thou plastic card).

And from the rear. I had to add a further layer of 20 thou plastic card as their was a gap at the top. The thin brass sheet allowed me to solder thin strips of brass either side to replace the vertical beading which was very prone to damage.

Here’s the boiler glued to the firebox. Further plastic card packing was needed to fill the gap created over the rear splasher by raising the box.

Here’s how it bolts to the running plate and cab front. Whilst I’ve been building the kit I’ve left off the bolts and nuts through the running plate as it’s very rigid withou them. I’ll put them back after painting to get a tight fit.

And in place later in the build.

Another error is the length of the smokebox, which is 2mm too long. Fortunately the extra length is at the rear behind the back row of rivets so is easy to rectify. If you don’t cut this back then the smokebox overhangs the front of the large steam pipe casting when it should be flush. I’ve seen a number of these on various websites with the smokebox overhanging. I’m not sure but I think this affects the David Andrews kit also.

The panel lines at the front were scribed on and the rivets added (Scale Hardware). In fact I think these are screws on the prototype as are the ones on the firebox cladding.

Once the firebox was sorted out, everything else was pretty much as per the kit instructions. One further mod I made to the boiler, was to make a representation of the front support bracket. I’ve not seen it on model before so maybe it’s a first?

Last edited:

![20180109_144244[1].jpg 20180109_144244[1].jpg](https://www.westernthunder.co.uk/data/attachments/82/82820-369950115780620eda6b7dbf0e4a36bd.jpg)

![20180109_145350[1].jpg 20180109_145350[1].jpg](https://www.westernthunder.co.uk/data/attachments/82/82821-5c0ab93721a4c868ed8a293ad0ad2e29.jpg)

![20180109_170745[1].jpg 20180109_170745[1].jpg](https://www.westernthunder.co.uk/data/attachments/82/82822-7a6c48d3ed29529c283cb7b719a709ac.jpg)