You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Edinburgh Princes St in EM

- Thread starter Ian N

- Start date

Hi Phil

i haven’t experienced a problem crashing the cutter, but a file for an A4 size sheet of any of the more common brick bonds is horrendously large ( @15mb iirc) and considerably impacts the performance of my old pc, especially when working with different layer or groups. IIRC, an A4 sheet of scribed brick bond will take well over 2 hrs to scribe. To reduce the impact on pc performance, I have A4 templates for various brick bonds, and draw the walls first, save the file, then start removing any of the template outside the lines for the wall, saving regularly. Having got bricked walls, I then add window and doors and remove the template bricks from them, again saving after every window/ door. Trying to get the file sized as small as possible as quick as possible. In my case it’s trying to get the best out of the limited memory and cpu of the pc.

Where I have had cutting related issue, it’s been either down to the plastic - not consistent in thickness or ‘hard’ areas within the sheet which grab the blade, or the cutting mat - loss of tack through excessive use on silhouettes own mats, or lack of adequate tack when 3rd party mats have been used. The latter failure usually occur with the blade not releasing from the plastic at the end of the cut/scribe and lifting and relocating the plastic from the sticky mat.

Most of the brick structures were commenced prior to obtaining the Silhouette, and all use either Wills or Slaters embossed sheets

i haven’t experienced a problem crashing the cutter, but a file for an A4 size sheet of any of the more common brick bonds is horrendously large ( @15mb iirc) and considerably impacts the performance of my old pc, especially when working with different layer or groups. IIRC, an A4 sheet of scribed brick bond will take well over 2 hrs to scribe. To reduce the impact on pc performance, I have A4 templates for various brick bonds, and draw the walls first, save the file, then start removing any of the template outside the lines for the wall, saving regularly. Having got bricked walls, I then add window and doors and remove the template bricks from them, again saving after every window/ door. Trying to get the file sized as small as possible as quick as possible. In my case it’s trying to get the best out of the limited memory and cpu of the pc.

Where I have had cutting related issue, it’s been either down to the plastic - not consistent in thickness or ‘hard’ areas within the sheet which grab the blade, or the cutting mat - loss of tack through excessive use on silhouettes own mats, or lack of adequate tack when 3rd party mats have been used. The latter failure usually occur with the blade not releasing from the plastic at the end of the cut/scribe and lifting and relocating the plastic from the sticky mat.

Most of the brick structures were commenced prior to obtaining the Silhouette, and all use either Wills or Slaters embossed sheets

Hi DaveIan, that really is a superb picture....

Merry Christmas to you and Martina.

Cheers Dave.

Are you suggesting a sense of deja-vu………? What lottery numbers should we use. But don’t tell everyone

I was anticipating a response to nothing moving with a comment about unfinished wiring. After how many years…….

Until I catch up with you at the club next year, all the very best to Fiona and yourself.

Hope you both have a wonderful Christmas.

Cheers

Ian

The work of Davy Scott, the first two bits of safety railing have the test fit on top of the small retaining wall. Not very obvious from the camera angle, he has captured both the solid and open posts in the prototype. Made from .5 wire and brass strip.

I’m always amazed at how much a relatively small item can make such a improvement to a scene and boost motivation.

The Transport Treasury image of the actual location

I’m always amazed at how much a relatively small item can make such a improvement to a scene and boost motivation.

The Transport Treasury image of the actual location

Thanks Dave. You've raised an interesting question I don't know the answer to.Lovely work and a very impressive looking layout in progress. As you say, the railings are an interesting feature with good attention to detail.

I wonder what the purpose was in having some posts "open"? They appear to be spaced quite randomly.

Dave.

My original assumption was that they were all solid, then corroded. The "single legged" post in the Transport Treasury image seems to discount that, as I would have expected them all to have corroded at the same rate, so it is unusual in being a one-off.

At the time of the TT photo, they would have been in that location for @55years. What sort of condition would they be in after 55years in an acid rain environment, assuming they hadn't been somewhere else first? Were the solids are the replacements for corroded opens....?

it gets further complicated, if you go the other side of the bridge, where the height difference between the goods and passenger stations was greater. The same style of railing exists, with what appears to be predominantly open posts nearest the camera. I guess at the end of the day, the company originally went for the cheapest manufacturing option

Dave F.

Western Thunderer

Hi Ian, to me as an engineer the fence posts could be T section iron notched out for the rail then bent back on it's self to form an I section hence the straight gap up the middle as the inner edges corroded away over the years, some more corroded than others so more or less of a gap.

Dave F.

Dave F.

Jim smith-wright

Western Thunderer

Hi IanI’ve never really been convinced that mass produced pointwork captures the flow of the prototype very well. It’s one of the reasons I changed to EM gauge, somewhat spookily, from N gauge! Dave Frank’s pointwork on Wharfeside 4mm - Wharfeside, a lifetime's project demonstrates “the flow“ perfectly, much better than my own efforts.

Totally agree and I think theres a couple of reasons. The main one being that real track is not built the same way that modellers lay track. Generally the track is routed to go to where it needs to go as smoothly as possible and the pointwork then built to fit it. What they dont do is have a bunch of standard points and work from them to route the track. Having studied the real thing a lot, pointwork with a straight road thats actually is straight (especially in station throats) is a very rare thing indeed. I think in my time ive only ever built one point that is truly straight in one direction. Everything else is always curved in some way.

The second reason is pointwork, even in tight locations is massive and mass produced stuff is quite simply miles too small. On New Street the ruling radius at the Bristol/Wolves end is 1 in 9 and that results in some quite mainline looking points but the reality is theres a 12mph restriction covering it all.

Lastly I don't think, no matter how careful you are, you can beat building the track in situe. The very process itself builds in a better flow in my opinion.

Keep up the good work

Jim

Last edited:

simond

Western Thunderer

I’d assumed they were cast iron. Possibly different patterns with same hole spacing, though I’d have expected them to be all the same. I doubt they’d have corroded through, the typical ones on promenades, open to winter storms & salt water etc seem to last a century or so…Thanks Dave. You've raised an interesting question I don't know the answer to.

My original assumption was that they were all solid, then corroded. The "single legged" post in the Transport Treasury image seems to discount that, as I would have expected them all to have corroded at the same rate, so it is unusual in being a one-off.

At the time of the TT photo, they would have been in that location for @55years. What sort of condition would they be in after 55years in an acid rain environment, assuming they hadn't been somewhere else first? Were the solids are the replacements for corroded opens....?

it gets further complicated, if you go the other side of the bridge, where the height difference between the goods and passenger stations was greater. The same style of railing exists, with what appears to be predominantly open posts nearest the camera. I guess at the end of the day, the company originally went for the cheapest manufacturing option

View attachment 201022

Quite a few years ago, I had a very interesting chat with a gent who used to work as part of the local S&T team at Princes St. Amongst other information gems, was the fact that he was involved in installing the banner repeater for a ground disc with sighting issues. The clearest photo I have of it is the Transport Treasury link above back in a June post. The image appears to show just one repeater, although the gent thought there were two on the bracket, one facing in each direction.

The closure of Hatton's, provided an opportunity to purchase a couple of Bachmann Banner Repeaters, seen here broken down into the component parts. The post has what looks like a 1mm steel wire for strength.

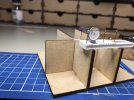

The bracket is assembled from Evergreen materials, and .45 brass rod for the handrails, placed together to check it looks right before final assembly, and cleaning up the soldering.

The closure of Hatton's, provided an opportunity to purchase a couple of Bachmann Banner Repeaters, seen here broken down into the component parts. The post has what looks like a 1mm steel wire for strength.

The bracket is assembled from Evergreen materials, and .45 brass rod for the handrails, placed together to check it looks right before final assembly, and cleaning up the soldering.

A quick second painting ( spilt the paint, then dropped the signal in it... after nearly finishing the original painting ) and it's ready for Model Rail Scotland. Handrail still looks rough at twice actual size, but will it be noticed when viewed from four feet away?

To me, the Bachman banner repeater appears to resemble the electrically lit versions, while the MSE/Wizard version seems to be the paraffin lamp version

To me, the Bachman banner repeater appears to resemble the electrically lit versions, while the MSE/Wizard version seems to be the paraffin lamp version

And finally the signal arrives on the layout. Plans to mount the bracket onto a fabricated post behind the wall went out the window on discovering that there was a block of wood supporting the retaining wall and the thick cardboard foundation for the paint factory where the post would have been. Plan B was a plastic peg screwed to the wood, and the signal bracket glued to that.