Arun Sharma

Western Thunderer

A project that I've been working on for some time as a spare time indulgence rather than as a kit design to sell is the rather angular but stylish class 455/8 as currently operated by SWT on its Waterloo suburban/commuter routes.

The 455 class units are based on the BREL designed 20metre Mk3 bodyshells which were common to a whole host of pre-privatisation EMUs and DMUs. Inded, the first class 150 DMU was built by taking a 455 bodyshell and modifying it so that a diesel engine and suitable transmission could be fitted.

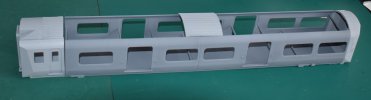

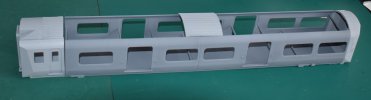

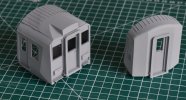

My basic design started life following a series of visits to photograph these units and then transposing the measurements into Autodesk Inventor with the following result [after 3D printing]:

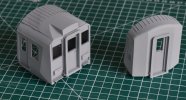

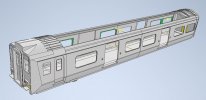

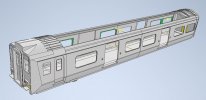

The CAD design itself of the whole DTSO car is:

The CAD design itself of the whole DTSO car is:

with separate doors and seats together with the various MU jumpers and underfloor bits to follow. The rear half of the car, when doubled, forms the entire TSO car which obviously save money and time. The power car of the 4-car set is almost the same as the TSO but has different bogies and a rather different air bag suspension mounting and some odd jumper connections on the rear end but nothing that can't be done in an hour or so when I get some time.

with separate doors and seats together with the various MU jumpers and underfloor bits to follow. The rear half of the car, when doubled, forms the entire TSO car which obviously save money and time. The power car of the 4-car set is almost the same as the TSO but has different bogies and a rather different air bag suspension mounting and some odd jumper connections on the rear end but nothing that can't be done in an hour or so when I get some time.

The 3D printed bodyshell had its first outing at the Guildford 7mm Trade show a couple of months ago in primer - which seemed appropriate as these cars are everyday stock on the Waterloo-Guildford routes:

The 455 class units are based on the BREL designed 20metre Mk3 bodyshells which were common to a whole host of pre-privatisation EMUs and DMUs. Inded, the first class 150 DMU was built by taking a 455 bodyshell and modifying it so that a diesel engine and suitable transmission could be fitted.

My basic design started life following a series of visits to photograph these units and then transposing the measurements into Autodesk Inventor with the following result [after 3D printing]:

The CAD design itself of the whole DTSO car is:

The CAD design itself of the whole DTSO car is: with separate doors and seats together with the various MU jumpers and underfloor bits to follow. The rear half of the car, when doubled, forms the entire TSO car which obviously save money and time. The power car of the 4-car set is almost the same as the TSO but has different bogies and a rather different air bag suspension mounting and some odd jumper connections on the rear end but nothing that can't be done in an hour or so when I get some time.

with separate doors and seats together with the various MU jumpers and underfloor bits to follow. The rear half of the car, when doubled, forms the entire TSO car which obviously save money and time. The power car of the 4-car set is almost the same as the TSO but has different bogies and a rather different air bag suspension mounting and some odd jumper connections on the rear end but nothing that can't be done in an hour or so when I get some time.The 3D printed bodyshell had its first outing at the Guildford 7mm Trade show a couple of months ago in primer - which seemed appropriate as these cars are everyday stock on the Waterloo-Guildford routes: