mike evans

Active Member

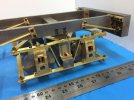

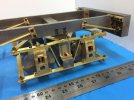

In the early part of this year I started scratch building a 3.5" Shay loco using Kozo's excellent book as my guide.

After a lengthy search I found the correct bevel gears and also placed an order for the boiler which should be here next week.

Here are a few photos of the work so far

i hope you enjoy these photos .

More photo as further progress is made

Mike

After a lengthy search I found the correct bevel gears and also placed an order for the boiler which should be here next week.

Here are a few photos of the work so far

i hope you enjoy these photos .

More photo as further progress is made

Mike