Good news, and some not quite so!

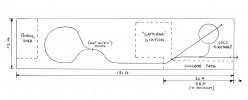

The loop curve is almost there at last, although for some reason, the final length decided to fight me all afternoon, until eventually submitting, and settling down nice and level under the bubble!

Ganger (part-time) Mr. O., came home from his "other" job, and found me slumped, exhausted but otherwise quite pleased with myself, sitting in the old chair leaning up against his potting shed! It seemed an opportune moment to take advantage of an extra pair of hands, so I roused myself, and declared that the new line was ready - and really should be tested!

Hurrah! It got there...!

Well... in a fashion! It slows right down, and grumbles a bit with my weight on the tender, but it does still keep going!

Mr. O., had a go - driving a couple of return trips along the whole length of the line for good measure - and I was able to closely observe how the wheels and motion behaved on the new formation.

I discovered to my dismay that the engine is fine when pulling, but worryingly, will not reverse on the curve.

The issue very much appears to be with the tender. A combination of the wheelbase, nylon tyres, and the necessarily short drawbar.

I had assumed that there would be a problem with the deep flanges rubbing too much on the inside of the rail. That is confirmed, and no doubt has a significant impact, but it is also clearly evident that with a longer wheelbase, the wheels also skid at an angle to the rail head. The latter point produces a distinct braking effect - which is quite noticeable when pushing the wagon by hand.

When the tender, and indeed other stock is hauled round such a tight bend, the angle of the drawbar tends to pull the vehicles toward the centreline of the curve, thus reducing flange contact to a minimum. Reversing the engine has completely the opposite effect; pushing the flanges so hard against the outer rail, that the wheels tend to climb.

Conventionally coned tyres would probably mitigate those actions.

I do wonder how the old LYR at Horwich managed with their flat profile, free-running wheels on fixed axles under similar circumstances?! Could it be, in part, the reason for their peculiar choice of three foot long drawbars?

Having said that, all the original vehicles had an extremely short, and common wheelbase. I had to extend that on my own stock, purely for stability when riding on it. That factor alone might yet turn out to be my undoing?!

For part of the test, I turned the loco around, to see how it coped with pulling away, under load, from a standing start on the curve...

Once again... slowly but surely... so no problem there!

I do take some comfort knowing that once the loop, and turntable at the other end of the line are completed, trains will only need to be hauled round with the loco leading at all times. I would of course, much prefer to find a more satisfactory solution though!

Incidentally, I had already tried one of Rich's superb bogies earlier - and that sailed round with so little effort, that I am convinced similarly fitted vehicles will be absolutely necessary for passenger carrying!

I just knew it!

I just knew it! we have

got to have a

TRAM for the railway now!

Shall have to think carefully about the overheads though?!

Back to the fun and games for today...

Some more worn and broken "Staffie" pavers (perfect for our use) have been donated to the cause, but needed collecting from the driveway.

"Might as well make use of the engine, before Mr. O., goes in for his tea" I thought!

Pete.

......I'm gone ..............

......I'm gone ..............