michael mott

Western Thunderer

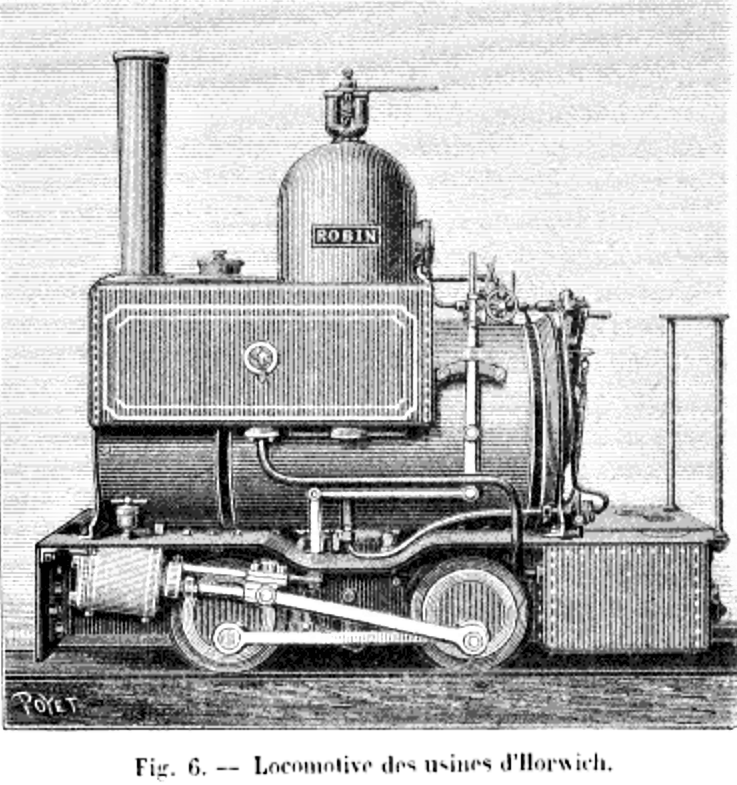

While waiting for Simon to go crawling under a carriage at SVR to look at the intricacies of the braking system for me , I have returned to an old project that is close to Peter Insoles heart. The Horwich shunting engines.

This also gave me the opportunity to clean up the workshop and put the drawings I have up on the wall.

about 4 years ago I purchased from the NRM 5 drawings of the Horwich shunting Engines including the following drawing numbers

3436 coloured rendering of general arrangement without saddle tank

3869 full size wheel bearing

3870 full size hornblock

3879 frame and boiler

6749 general arrangement showing the saddle tank

I am using these drawings to prepare a 2D cad set of drawings with all the major areas on separate named layers Full size in order to avoid the sorts of confusions that are encountered with old stacked drawings of our subjects.

I am a bit old school in that I only have Auto-cad Lt 2000 but it is more than sufficient for my needs, and I am not prepared to go through the 3D learning curve.

As part of my discussions with the members on Peter Insole's thread "Finescale of a sort" there are all sorts of hidden gems, not all accurate in these old drawings, I say this with all due respect having learned how to draw with a board and T square.

Being as these drawings are drawn and printed and Digitized By the NRM at 3 inches to the foot scale and I have both versions, it is still very time consuming and often having to resort to laying the scale ruler (taboo) over the print to confirm or extrapolate a given dimension that is suspect.

That said I am enjoying the process of detection and will hopefully eventually to have a complete set of all the components of the little shunting engines that worked so hard at Horwich in very important roles as aids to building the large standard gauge locomotives, shifting and carrying parts around the plant.

I have already partially built models of these locos in different scales, working from these old drawings plus the ones that were drawn by Roy C Link for the model community. these were made by constantly converting scales and dimensions, and making compromises regarding gauges.

I will put up a thread about the little Horwich locos in the appropriate area. with the background models already in existence, my plan is also to build another model to the scale of 3/4 inch to the foot so the gauge will be set to 1 1/8th inches I am not going to conflate the imperial and Si (metric) systems Which has been fostered on the model railway community for decades, I think in UK imperial units was taught them that way in school and the data that I have to hand is drawn in those same units.

Once the drawings are done, they will be able to be manipulated into any scale or system using the tools we now have in our hands, and it is so much easier not having to convert the numbers as I am drawing.

Michael

This also gave me the opportunity to clean up the workshop and put the drawings I have up on the wall.

about 4 years ago I purchased from the NRM 5 drawings of the Horwich shunting Engines including the following drawing numbers

3436 coloured rendering of general arrangement without saddle tank

3869 full size wheel bearing

3870 full size hornblock

3879 frame and boiler

6749 general arrangement showing the saddle tank

I am using these drawings to prepare a 2D cad set of drawings with all the major areas on separate named layers Full size in order to avoid the sorts of confusions that are encountered with old stacked drawings of our subjects.

I am a bit old school in that I only have Auto-cad Lt 2000 but it is more than sufficient for my needs, and I am not prepared to go through the 3D learning curve.

As part of my discussions with the members on Peter Insole's thread "Finescale of a sort" there are all sorts of hidden gems, not all accurate in these old drawings, I say this with all due respect having learned how to draw with a board and T square.

Being as these drawings are drawn and printed and Digitized By the NRM at 3 inches to the foot scale and I have both versions, it is still very time consuming and often having to resort to laying the scale ruler (taboo) over the print to confirm or extrapolate a given dimension that is suspect.

That said I am enjoying the process of detection and will hopefully eventually to have a complete set of all the components of the little shunting engines that worked so hard at Horwich in very important roles as aids to building the large standard gauge locomotives, shifting and carrying parts around the plant.

I have already partially built models of these locos in different scales, working from these old drawings plus the ones that were drawn by Roy C Link for the model community. these were made by constantly converting scales and dimensions, and making compromises regarding gauges.

I will put up a thread about the little Horwich locos in the appropriate area. with the background models already in existence, my plan is also to build another model to the scale of 3/4 inch to the foot so the gauge will be set to 1 1/8th inches I am not going to conflate the imperial and Si (metric) systems Which has been fostered on the model railway community for decades, I think in UK imperial units was taught them that way in school and the data that I have to hand is drawn in those same units.

Once the drawings are done, they will be able to be manipulated into any scale or system using the tools we now have in our hands, and it is so much easier not having to convert the numbers as I am drawing.

Michael