Thank you JB and Michael. I am sorry it has taken a while to reply, but I am still struggling a bit with my health. Thanks for posting the lovely pics too Tom, the memories are much appreciated !!

I have managed to potter more positively over the last couple of days with some short sessions at the workbench. All credit is due to Mr, G, otherwise known as "Glenn..." of this parish, who is not just a champion "Lankey" transfer producer, as it so happens!

Many of you, dear readers may recall the trouble I got into some time ago when dismantling a much prized, hand charging torch while searching for some useful gear wheels?! It unfortunately turned out that the ratios were not quite right anyway, so a careful reassembly and complete rethink was required! I have no idea precisely what those ratios are in mathematical terms, but by looking at a timepiece I can surmise that the anticlockwise travel limit on the loco regulator handle is around twelve minutes, while the speed control unit knob has to rotate clockwise from the off stop to a full forty minutes !! While I may get confused by numbers, I have always enjoyed a bit of geometry, especially when drawing with a good, old fashioned pencil on paper! After covering an A4 sheet with masses of pin holes and swirly compass lines, I was able to find a perfect, if overly large visual solution. Great stuff. but there were two new problems: Firstly; my inkjet printer has completely packed up, and frankly I have way too many other things to chuck precious pennies at, so I am relying on a little outside assistance for reducing artwork, (reference the aforementioned Glenn there) and secondly; although I have some suitable brass in stock, I will have to cut my own teeth!!

Back in the day, I would have printed the gears on some thin paper, reached for a tin of spray mount, slapped it down and started cutting round the lines, but once again, I do not have any similar sort of smooth, "tacky" glue to hand now! Glenn phoned to let me know that the gear drawing had come out nice and clearly, but then asked me what I was hoping to do with it - and as I was bemoaning the lack of materials in reply, the champion had his great idea!

He has one of those clever, computer controlled, paper cutter thingies at home, so offered to re do the job on self adhesive labels - all ready to just peel off, stick and go...

Luvly jubly jobbie!

Well. on paper anyway ??

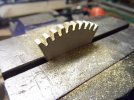

The labels do get a bit mashed up where the piece is clamped in the vice, but provided an ample area is kept clear of the teeth, the template remained nicely stable throughout all the subsequent hacking activity...

The reflected light does make the job look rather rough in places, and it was certainly jolly hard going most of the time, with the needle files frequently jamming when drawing down into the angles!

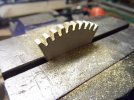

I am quite pleased with my first ever, seriously crazy attempt at gear cutting...

There is still a bit of meat twinkling around the teeth, but I felt that it was better to leave something to trim back when offering up the second wheel, rather than end up having too much rattle with the inevitable odd pincher here and there ?!

That last mentioned, widdy wheel will be a load of fun for this afternoon?!

Wish me luck !!

Pete.