Yorkshire Dave

Western Thunderer

Another loco was recently acquired - a Roco DBAG Br 212 (ex V100) in Orientrot livery.

It has already received some weathering using AK Interactive and Vallejo acrylic paint, Tamiya weathering powders and oil washes. I also attempted to fade some of the larger panels by rubbing in white Tamiya weathering powder which is subtle but noticeable.

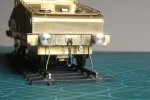

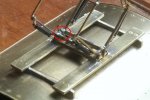

While the loco was on the bench I added the Wendezug (push/pull) connections to the buffer beams andreplaced the flimsy end handrail stanchions with 0.45mm brass wire. The hand knobs at the top were formed with a drop of canopy glue.

Rust was dabbed along the sill to represent wear and tear.

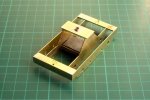

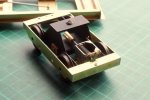

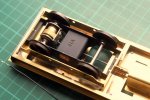

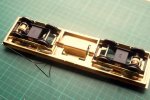

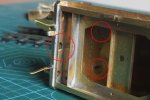

One thing I'm toying with is removing the NEM coupler box from the bogies and mounting the coupler on the chassis which means I can install the four air hoses and steam heat hose on both ends.

It has already received some weathering using AK Interactive and Vallejo acrylic paint, Tamiya weathering powders and oil washes. I also attempted to fade some of the larger panels by rubbing in white Tamiya weathering powder which is subtle but noticeable.

While the loco was on the bench I added the Wendezug (push/pull) connections to the buffer beams andreplaced the flimsy end handrail stanchions with 0.45mm brass wire. The hand knobs at the top were formed with a drop of canopy glue.

Rust was dabbed along the sill to represent wear and tear.

One thing I'm toying with is removing the NEM coupler box from the bogies and mounting the coupler on the chassis which means I can install the four air hoses and steam heat hose on both ends.

after a heart op 15 months ago, I started faffing around wielding a hot stick

after a heart op 15 months ago, I started faffing around wielding a hot stick