PeteB

Active Member

I ate a couple of bars of that stuff once, felt oh so sick never to return.

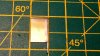

I've made a little progress with the pull-push mech. The intermediate link was next.

I cut a right angle 1mm wide from 0.018" ns sheet and put the bend in and the hole for the pivot.

As I'm working from Brian's splendid photo I'm having to guess the dimensions and the place to mount onto the boiler back.

Took quite a bit of time and two attempts before I was happy.

Next was a bush to go between the link and the boiler back. I made the shaft from a pin (I do like my pins, they work so well) Hexing the head, then with a scalpel cut away the top so that it looks like a nut. I ended up crossed eyed!!!!

Now to see if it all fits.

Thought I'd add the rest just to see how it looks.

Ok I think that works Well happy.

Well happy.

Now it's on to the links. The one from the shaft which enters the cab and attaches to the intermediate link is, I think, straight forward. An adjustable rod with fork ends.

It's the link between the intermediate and the regulator, that's the tricky one as there are no pics of it. So I thought a fork end at the inter end with a rod that screws into a ns square rod and filled down to a tongue to fit into the regulator slot.

I hope that makes sense. If anyone has a better idea, then speak up.

Pete

I've made a little progress with the pull-push mech. The intermediate link was next.

I cut a right angle 1mm wide from 0.018" ns sheet and put the bend in and the hole for the pivot.

As I'm working from Brian's splendid photo I'm having to guess the dimensions and the place to mount onto the boiler back.

Took quite a bit of time and two attempts before I was happy.

Next was a bush to go between the link and the boiler back. I made the shaft from a pin (I do like my pins, they work so well) Hexing the head, then with a scalpel cut away the top so that it looks like a nut. I ended up crossed eyed!!!!

Now to see if it all fits.

Thought I'd add the rest just to see how it looks.

Ok I think that works

Well happy.

Well happy.Now it's on to the links. The one from the shaft which enters the cab and attaches to the intermediate link is, I think, straight forward. An adjustable rod with fork ends.

It's the link between the intermediate and the regulator, that's the tricky one as there are no pics of it. So I thought a fork end at the inter end with a rod that screws into a ns square rod and filled down to a tongue to fit into the regulator slot.

I hope that makes sense. If anyone has a better idea, then speak up.

Pete

so a new fork end was constructed and a slightly longer one.

so a new fork end was constructed and a slightly longer one.