Heather Kay

Western Thunderer

What should I do with several half-started and nearly-completed commissions piled up on the workbench? Why, start a new build, of course!

I was sure I'd already started a thread for this build, but I can't immediately lay my mouse on it. So, here's the story so far!

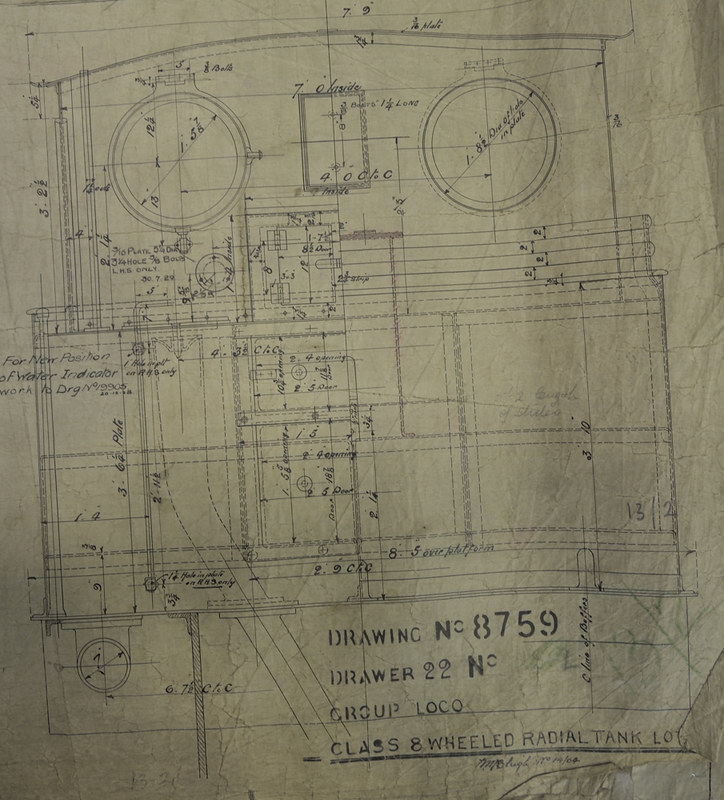

A returning client, which is always a nice thing to have, asked me if I would build a Lancashire & Yorkshire 2-4-2T for him. He handed me a kit (an original George Norton), and instructions as to which loco he wanted. He models post-War LMS, so the livery would be plain black with simple lettering and numbering. A short-bunkered, Belpaire-boilered, motor-fitted example, inside motion and working radial trucks with 10650 being the selected loco.

On assessing the box contents, it was fairly obvious conversion to the required format would be rather more complex than either of us anticipated. Let's just say I felt it wiser to buy a more up-to-date kit for the type, and happily the client agreed. Knowing my aversion to complex engineering, I commissioned Paul Penn-Sayers (@Locomodels) to make the chassis for me. With his permission, I will share some his progress photos here. Perhaps Paul might offer some pointers to the methods he used, and problems he encountered, in due course.

The kit, from Lanky Kits, motor, gearbox (ABC), wheels (Slater's) and Laurie Griffin motion parts were purchased at a show, and Paul took them back to France with him.

It soon transpired that the inside motion parts weren't really quite right. Paul set to and researched, and decided the simplest way forward was to make new parts. This is why I prefer to let people who know what they're doing do this stuff for me! Patterns were made for the motion plate and crank webs, which were then cut on Paul's profile miller.

Slide bars, pendulum and valve linkage.

Motion plate, slide bars, crossheads and piston rods.

Crank axle and con rods.

Everything being assembled in the chassis.

The end result of all that work was collected from Paul at Telford in 2016. A splendid piece of model engineering it is, too.

The reversing lever is currently held in place by a temporary bar fixed to a chassis cross member. I shall have to think carefully about how it gets attached to the reach rod so the body can be removed.

Paul also constructed the running plate, as it needed some slight modification to accommodate the motion. So, on the face of it, there's not a lot left for me to do!

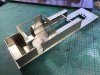

Ah, yes, those radial trucks. Let's show you those:

Well, one of them, anyway. In order to continue the build, I had to remove the rear truck from the chassis in order to access the body retaining bolt under the bunker. The unit is bolted into the chassis using six tiny screws. As you can see, it's quite a work of art. The original plan had been to potentially use LG trucks, but Paul ended up making these from scratch. Under the phosphor bronze spring is an engineered bearing tube that really does slide from side to side radially. Marvellous.

What was left in the box, as far as etched parts were concerned, amounted to this lot. The boiler tube is rolled. There are some duplicate parts, as the kit can make both long and short bunker variants of the type.

Castings and things. I will need to find a suitable reference for the cab fittings. It's something not really covered in the instructions in great depth, so I will have to do some rummaging around to see what turns up. There are parts here for the motor-fitting pipework, but not something I can identify as the control unit for the driver's side smokebox. Looking at photos, though, it's not something amazingly complex, so should be relatively easy to fabricate from tube and wire.

This was where I got to after a day of studying photos, the instructions, and the parts in the box. Cab and bunker floor, bunker front, sides and back. Parts are not identified with numbers on the etch frets (did I mention this kit is entirely nickel silver?) so, as with other builds, I've taken the precaution of writing the part numbers on the etched parts themselves. Apart from the boiler, firebox and roof, all the main parts are nice and square. No fancy flares or rounded edges here, just straight up Northern common sense. This will make the build nice and easy, though a little ingenuity is required to make the joins where no tabs exist.

So far, so good. With the relatively box-like bodywork, the superstructure ought to come together pretty quickly on this build. Not having to fret over the chassis means the overall build ought not take that long. Famous last words!

The one thing I seemed to be missing from reference photos was a good rear end view. As I was flicking through one of the reference works, there was a nice clear photo of the backside of 10650 itself! Now I know how the motor-fitted gear was attached to the bunker, so that's brilliant.

Oddly, I can't find anything in the box about the bunker coal door. There is a preserved 2-4-2T in the national collection, so I hope someone has got a shot in the cab that shows what the front of the bunker looks like in the cab. The firebox backhead fittings might have to be interpreted from similar Belpaire boiler locos of the period, although being an enclosed cab it may be possible to get away with some modeller's licence. The cab door handrails are quite obviously tapered, so I shall investigate Mr Griffin's selection for something suitable. Likewise, I think cast lamp brackets might set the model off nicely.

Well, the weather seems to be finally warming up, so work on builds in the queue for paint shop action might take precedence over this loco for a while.

I was sure I'd already started a thread for this build, but I can't immediately lay my mouse on it. So, here's the story so far!

A returning client, which is always a nice thing to have, asked me if I would build a Lancashire & Yorkshire 2-4-2T for him. He handed me a kit (an original George Norton), and instructions as to which loco he wanted. He models post-War LMS, so the livery would be plain black with simple lettering and numbering. A short-bunkered, Belpaire-boilered, motor-fitted example, inside motion and working radial trucks with 10650 being the selected loco.

On assessing the box contents, it was fairly obvious conversion to the required format would be rather more complex than either of us anticipated. Let's just say I felt it wiser to buy a more up-to-date kit for the type, and happily the client agreed. Knowing my aversion to complex engineering, I commissioned Paul Penn-Sayers (@Locomodels) to make the chassis for me. With his permission, I will share some his progress photos here. Perhaps Paul might offer some pointers to the methods he used, and problems he encountered, in due course.

The kit, from Lanky Kits, motor, gearbox (ABC), wheels (Slater's) and Laurie Griffin motion parts were purchased at a show, and Paul took them back to France with him.

It soon transpired that the inside motion parts weren't really quite right. Paul set to and researched, and decided the simplest way forward was to make new parts. This is why I prefer to let people who know what they're doing do this stuff for me! Patterns were made for the motion plate and crank webs, which were then cut on Paul's profile miller.

Slide bars, pendulum and valve linkage.

Motion plate, slide bars, crossheads and piston rods.

Crank axle and con rods.

Everything being assembled in the chassis.

The end result of all that work was collected from Paul at Telford in 2016. A splendid piece of model engineering it is, too.

The reversing lever is currently held in place by a temporary bar fixed to a chassis cross member. I shall have to think carefully about how it gets attached to the reach rod so the body can be removed.

Paul also constructed the running plate, as it needed some slight modification to accommodate the motion. So, on the face of it, there's not a lot left for me to do!

Ah, yes, those radial trucks. Let's show you those:

Well, one of them, anyway. In order to continue the build, I had to remove the rear truck from the chassis in order to access the body retaining bolt under the bunker. The unit is bolted into the chassis using six tiny screws. As you can see, it's quite a work of art. The original plan had been to potentially use LG trucks, but Paul ended up making these from scratch. Under the phosphor bronze spring is an engineered bearing tube that really does slide from side to side radially. Marvellous.

What was left in the box, as far as etched parts were concerned, amounted to this lot. The boiler tube is rolled. There are some duplicate parts, as the kit can make both long and short bunker variants of the type.

Castings and things. I will need to find a suitable reference for the cab fittings. It's something not really covered in the instructions in great depth, so I will have to do some rummaging around to see what turns up. There are parts here for the motor-fitting pipework, but not something I can identify as the control unit for the driver's side smokebox. Looking at photos, though, it's not something amazingly complex, so should be relatively easy to fabricate from tube and wire.

This was where I got to after a day of studying photos, the instructions, and the parts in the box. Cab and bunker floor, bunker front, sides and back. Parts are not identified with numbers on the etch frets (did I mention this kit is entirely nickel silver?) so, as with other builds, I've taken the precaution of writing the part numbers on the etched parts themselves. Apart from the boiler, firebox and roof, all the main parts are nice and square. No fancy flares or rounded edges here, just straight up Northern common sense. This will make the build nice and easy, though a little ingenuity is required to make the joins where no tabs exist.

So far, so good. With the relatively box-like bodywork, the superstructure ought to come together pretty quickly on this build. Not having to fret over the chassis means the overall build ought not take that long. Famous last words!

The one thing I seemed to be missing from reference photos was a good rear end view. As I was flicking through one of the reference works, there was a nice clear photo of the backside of 10650 itself! Now I know how the motor-fitted gear was attached to the bunker, so that's brilliant.

Oddly, I can't find anything in the box about the bunker coal door. There is a preserved 2-4-2T in the national collection, so I hope someone has got a shot in the cab that shows what the front of the bunker looks like in the cab. The firebox backhead fittings might have to be interpreted from similar Belpaire boiler locos of the period, although being an enclosed cab it may be possible to get away with some modeller's licence. The cab door handrails are quite obviously tapered, so I shall investigate Mr Griffin's selection for something suitable. Likewise, I think cast lamp brackets might set the model off nicely.

Well, the weather seems to be finally warming up, so work on builds in the queue for paint shop action might take precedence over this loco for a while.