You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Mickoo's Commercial Workbench

- Thread starter mickoo

- Start date

Yorkshire Dave

Western Thunderer

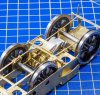

I've cut away the outside plate so that the rear wheels can be slid off the axles, this plate is near invisible on the inside of the rear tender frames, it's basically there to hold the two lower transverse plates in position. I didn't cut the front away as that axle and wheels can simply be lifted in and out.

Rather than cut away the outside plate couldn't you have just slotted the rear axle frames, turned the top hat bearing into a Perseverance style slotted bearing (which would have been retained on the axles) or a retained bearing with a flat similar to those in the Atlas China drives and held the ensemble in with a keeper plate?

mickoo

Western Thunderer

I could, but I wanted something the painter would understandRather than cut away the outside plate couldn't you have just slotted the rear axle frames, turned the top hat bearing into a Perseverance style slotted bearing (which would have been retained on the axles) or a retained bearing with a flat similar to those in the Atlas China drives and held the ensemble in with a keeper plate?

and be able take in and with ease

and be able take in and with ease  , designing something akin to the internals of a Gloch would probably result in it turning into a lawn dart

, designing something akin to the internals of a Gloch would probably result in it turning into a lawn dart

The only reason you need to cut the outside plate is if you need to get the wheels off the axle, if you want the axle to lift out then it doesn't need cutting, it makes no odds if it is as it's inside behind the real frames.

Anyway, this is what I came up with and there's probably a dozen ways to achieve the same result.

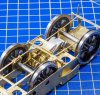

The rear axle bearing framework was slotted, a new carrier piece fabricated and the bearings flipped around and fitted; these then drop into the slots and ensure it's all lined up correctly. Finally two screws secure the plate to the rear stay.

Like so

Max M

Western Thunderer

I've actually got two, though the second one is a much longer term project and will be more detailed for my own collection....

I only have one but that is another story...

As you go through the build would it be possible to indicate the extra detail you are likely to add to #2 please?

I'm just about to embark on mine so it would be nice to have some pointers.

Dikitriki has already pointed me to the Ragstone brake components (thank you Dt) and anything else would be much appreciated.

mickoo

Western Thunderer

My version is simply what I want as a model and not a reflection of the current kit. I think it's important to get that across from the start. If you've followed the W1 and B1 thread it's not hard to work out where most of the work will be.

First off would be the smoke box. It needs opening out and a whole new interior added, blast pipe, tube plate, superheated header and associated pipework. The next area is the brakes, cookie cut etches are fine and make up well but I'd want correct profile components so you're looking at all new brake gear, all of it from brake cylinder right through to resin shoes and cast hangers. Next are the springs which are currently laminated, these will be replaced.woth either cast or etched ones made up like the real spring, eg spring plates, wrapper and horn block fixing, fiddly but a single run of cast springs may be prohibitive. New cast hornguides would also on the cards, either 3rd party or make my own.

A new middle cylinder block is planned, I've not looked too deeply at the kit one and am blindly assuming it'll be the usual flat three sided tub, it may be possible to tweak the kit one but I suspect it'll be a case of working up a new one.

All of the above could/may be developed with a eye to possibly upgrading the current kit, if there was enough interest or demand, I suspect not as it is a quote path I tread lol.

Hard to say that as the current kit is already very good but these are areas I'd like to change personally.

The following would not be considered an upgrade. For me the biggest buzz is the frames, stays and minutia of detail. The mantra 'you cannot see it on the track' is invalid, for me, I want the insides to be as good as possible within the constraints of O fine. That detail and complexity is what I enjoy and want out of my hobby.

So you're basically looking at a whole new set of frames from the ground up, front to rear, brackets, stays, cylinder blocks, motion brackets, ash pan, whatever can be squeezed in. Whilst you're doing all that, it is prudent to spend a little time researching the rear end and seeing if the currently missing members the kit does not build can become a reality.

I've also not decided on a prototype engine yet, it'll not be a Duchess that's for sure, but I may also need to look at the tender as some were fitted with the part welded/riveted version so I may need some new side sheets and little details there as well.

As I said, a slightly longer term project for me as other stuff is progressed.

First off would be the smoke box. It needs opening out and a whole new interior added, blast pipe, tube plate, superheated header and associated pipework. The next area is the brakes, cookie cut etches are fine and make up well but I'd want correct profile components so you're looking at all new brake gear, all of it from brake cylinder right through to resin shoes and cast hangers. Next are the springs which are currently laminated, these will be replaced.woth either cast or etched ones made up like the real spring, eg spring plates, wrapper and horn block fixing, fiddly but a single run of cast springs may be prohibitive. New cast hornguides would also on the cards, either 3rd party or make my own.

A new middle cylinder block is planned, I've not looked too deeply at the kit one and am blindly assuming it'll be the usual flat three sided tub, it may be possible to tweak the kit one but I suspect it'll be a case of working up a new one.

All of the above could/may be developed with a eye to possibly upgrading the current kit, if there was enough interest or demand, I suspect not as it is a quote path I tread lol.

Hard to say that as the current kit is already very good but these are areas I'd like to change personally.

The following would not be considered an upgrade. For me the biggest buzz is the frames, stays and minutia of detail. The mantra 'you cannot see it on the track' is invalid, for me, I want the insides to be as good as possible within the constraints of O fine. That detail and complexity is what I enjoy and want out of my hobby.

So you're basically looking at a whole new set of frames from the ground up, front to rear, brackets, stays, cylinder blocks, motion brackets, ash pan, whatever can be squeezed in. Whilst you're doing all that, it is prudent to spend a little time researching the rear end and seeing if the currently missing members the kit does not build can become a reality.

I've also not decided on a prototype engine yet, it'll not be a Duchess that's for sure, but I may also need to look at the tender as some were fitted with the part welded/riveted version so I may need some new side sheets and little details there as well.

As I said, a slightly longer term project for me as other stuff is progressed.

mickoo

Western Thunderer

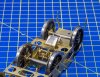

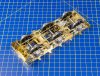

Little bit of progress, lot of work but little progress, brake rigging, there's no short cuts here, just keep plugging away.

As is my usual way of doing this, pivot at the front and clip the hangers in with wire.

This time I altered the rear ones, from just plain wire to wire in a tube which is fixed to the frames, the tube stops the rear brake hangers wobbling left to right and strengthens it all up and keeps it straight, you could put tubes all along...I forgot, despite the instructions recommending it.

Right way up and rolling nicely with no shorts.

Side below view.

Whilst the brake rigging slips in and out it's not as slick as I'd like, primarily the intermediate brake beam which is very close to the rear stay and scoop protection plate. The plate is angled to match the scoop face and the beam has to get past this and underneath the angled plate. Fortunately the pull rods are flexible enough to allow them to bow gently to get the intermediate beam around the scoop protection plate.

I'm going to ponder this and think I'll end up taking the protection plate off the stay and fixing it to the brake beam. I did initially think I'd assembled something wrong somewhere, like the scoop is too far forward by 0.5 mm and the brakes assembled incorrectly. But so many parts interact and have to align with each other, it's almost impossible to get one piece wrong.....unless a half dozen pieces are all wrong as well. It's probably just very tight under there on the real tender.

There's some wire stubs up front to add for the water pipes and then it's onto the interesting stuff up top.

As is my usual way of doing this, pivot at the front and clip the hangers in with wire.

This time I altered the rear ones, from just plain wire to wire in a tube which is fixed to the frames, the tube stops the rear brake hangers wobbling left to right and strengthens it all up and keeps it straight, you could put tubes all along...I forgot, despite the instructions recommending it.

Right way up and rolling nicely with no shorts.

Side below view.

Whilst the brake rigging slips in and out it's not as slick as I'd like, primarily the intermediate brake beam which is very close to the rear stay and scoop protection plate. The plate is angled to match the scoop face and the beam has to get past this and underneath the angled plate. Fortunately the pull rods are flexible enough to allow them to bow gently to get the intermediate beam around the scoop protection plate.

I'm going to ponder this and think I'll end up taking the protection plate off the stay and fixing it to the brake beam. I did initially think I'd assembled something wrong somewhere, like the scoop is too far forward by 0.5 mm and the brakes assembled incorrectly. But so many parts interact and have to align with each other, it's almost impossible to get one piece wrong.....unless a half dozen pieces are all wrong as well. It's probably just very tight under there on the real tender.

There's some wire stubs up front to add for the water pipes and then it's onto the interesting stuff up top.

Cliff Williams

Western Thunderer

This was my fix for the brakegear. Bolts to hold the brakegear on, with small tubes to act as spacers and keep the alignment and stop shorting at a later date with handling and wear and tear.

I think they are 14BA bolts.

Please excuse the pic quality, it was an early digital camera fro ma rather shocking 21/11/2001!

I think they are 14BA bolts.

Please excuse the pic quality, it was an early digital camera fro ma rather shocking 21/11/2001!

mickoo

Western Thunderer

Nice solution.

I think I'm going to have to split the front pull rods off, the ones with the slack adjusters on. The problem is as one rigid set up you cannot easily get the intermediate brake beam past the scoop cover.

The whole lot needs to go forward 0.5 mm then down and back when fitting. With the front end fixed to the brake lay shaft that's no possible without flexing the other rods. I think I've worked out how to hide the joint so will try this evening and see how it goes.

I think I'm going to have to split the front pull rods off, the ones with the slack adjusters on. The problem is as one rigid set up you cannot easily get the intermediate brake beam past the scoop cover.

The whole lot needs to go forward 0.5 mm then down and back when fitting. With the front end fixed to the brake lay shaft that's no possible without flexing the other rods. I think I've worked out how to hide the joint so will try this evening and see how it goes.

Cliff Williams

Western Thunderer

I remember that shoogle move now.

I cheated and removed the lower section of the fork, so the rods just dropped on without a shoogle which proved impossible to make stable IMHO.

You could do similar and fit the removed piece of fork to the underside on the linkage. I should have done that on all three that I built. But didn’t.

I cheated and removed the lower section of the fork, so the rods just dropped on without a shoogle which proved impossible to make stable IMHO.

You could do similar and fit the removed piece of fork to the underside on the linkage. I should have done that on all three that I built. But didn’t.

warren haywood

Western Thunderer

warren haywood

Western Thunderer

Who knows, good few years ago that one lol

I probably just sprayed the whole lot black and cleaned the treads afterwards, much quicker

I probably just sprayed the whole lot black and cleaned the treads afterwards, much quicker

mickoo

Western Thunderer

Well that's one way of doing it  If you're still happy to do that then I'll solder this one all up

If you're still happy to do that then I'll solder this one all up

But if you don't then I've managed to work around it.

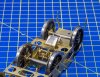

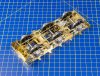

Clearly the issue is with the scoop protection plate, so off it came, it's 0.5 mm thick and in it's place I added a thin 5 thou plate directly onto the scoop front. This also means that it is always at the right angle to the scoop face, not so easy with the previous fitting.

As can be seen, the intermediate brake beam now just squeaks past the scoop cover, actually there's a conflict of about 0.1-0.2 mm but the scoop uptake is mounted on a long finger of brass so it's very easy to just ease it back a fraction and the beam drops into place.

All fitted and looking good

Right, on with the rest now

If you're still happy to do that then I'll solder this one all up

If you're still happy to do that then I'll solder this one all up

But if you don't then I've managed to work around it.

Clearly the issue is with the scoop protection plate, so off it came, it's 0.5 mm thick and in it's place I added a thin 5 thou plate directly onto the scoop front. This also means that it is always at the right angle to the scoop face, not so easy with the previous fitting.

As can be seen, the intermediate brake beam now just squeaks past the scoop cover, actually there's a conflict of about 0.1-0.2 mm but the scoop uptake is mounted on a long finger of brass so it's very easy to just ease it back a fraction and the beam drops into place.

All fitted and looking good

Right, on with the rest now

oldravendale

Western Thunderer

Warren - that Photobucket stamp is a total PIA.Here’s the one I did if it helps, probably not

View attachment 99317 View attachment 99318 View attachment 99319

Brian

warren haywood

Western Thunderer

Old photos I lifted from o gauge guild site. Don’t have them anymoreWarren - that Photobucket stamp is a total PIA.

Brian

oldravendale

Western Thunderer

That's a relief for the future, Warren!

Brian

Brian

mickoo

Western Thunderer

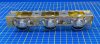

Moving on, not as quick as I planned, but getting there.

The main frames for the tender, simply fold up items and a pile of castings to add. The difference between a nice LMS white metal axle box casting and a fishing weight, is something that can only be measured by the hadron collector in Lucerne I've decided.

Luckily I have two tenders so ended up raiding mine to replace the damaged ones, I'll speak nicely to F7 stores at Kettering and procure a couple of spares. In my defence, one didn't quite sit flat and it was the act of trying to get the solder to fill the gap that melted it.

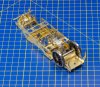

Anyway, the frame shell, there's a still a few little bits to add...but not this evening.

Now with the chassis inserted.

The buffers will be converted to self contained and then fitted later; the step treads I've found are prone to damage during the build, so they will go on almost last. The drag beam buffers will be trimmed and fitted once the engine is done and I can check clearances on the 6' curve.

The main frames for the tender, simply fold up items and a pile of castings to add. The difference between a nice LMS white metal axle box casting and a fishing weight, is something that can only be measured by the hadron collector in Lucerne I've decided.

Luckily I have two tenders so ended up raiding mine to replace the damaged ones, I'll speak nicely to F7 stores at Kettering and procure a couple of spares. In my defence, one didn't quite sit flat and it was the act of trying to get the solder to fill the gap that melted it.

Anyway, the frame shell, there's a still a few little bits to add...but not this evening.

Now with the chassis inserted.

The buffers will be converted to self contained and then fitted later; the step treads I've found are prone to damage during the build, so they will go on almost last. The drag beam buffers will be trimmed and fitted once the engine is done and I can check clearances on the 6' curve.

warren haywood

Western Thunderer

Time for the spanner

The springs could do with being removable. The loco is going into red so they need to be black and the frames red.

If you can’t then fine, I will have to hand paint them but never as neat. It’s a pig getting the yellow around the cut outs too as the line stops and starts so there will be a gap

Sorry mate

The springs could do with being removable. The loco is going into red so they need to be black and the frames red.

If you can’t then fine, I will have to hand paint them but never as neat. It’s a pig getting the yellow around the cut outs too as the line stops and starts so there will be a gap

Sorry mate

mickoo

Western Thunderer

Bugga, forgot about that!

Okay, the only way the white metal is going to come off is with some serious heat (which may damage them), but first the straps will probably need cutting off, they're twisted in so won't come out easy.

The right way is of course to pull all the WM off, get new springs and axle boxes (I've got my spare tender here.....minus two axle boxes as two have already been turned into fishing weights), join the spring to the axle box, nip the nubs off the rear of the spring damper brackets. It should then be possible to slip that assembly up under the straps and use the main axle box spigot to hold it all in place; it'll have to be an adhesive once painted though. This is the shortest, but higher risk option.

Another option is pull this set of frames to one side for my engine, though I'm not yet sure which one I'm doing; but I have kept the cut off rear steps safe. Then build my tender frames along the lines of the above whilst getting two new axle boxes from Finney7. This'd be the longer fall back option.

I'll mull it over for a few days, it's not the end of the world and doesn't impact on the body above, or the chassis already completed.

Okay, the only way the white metal is going to come off is with some serious heat (which may damage them), but first the straps will probably need cutting off, they're twisted in so won't come out easy.

The right way is of course to pull all the WM off, get new springs and axle boxes (I've got my spare tender here.....minus two axle boxes as two have already been turned into fishing weights), join the spring to the axle box, nip the nubs off the rear of the spring damper brackets. It should then be possible to slip that assembly up under the straps and use the main axle box spigot to hold it all in place; it'll have to be an adhesive once painted though. This is the shortest, but higher risk option.

Another option is pull this set of frames to one side for my engine, though I'm not yet sure which one I'm doing; but I have kept the cut off rear steps safe. Then build my tender frames along the lines of the above whilst getting two new axle boxes from Finney7. This'd be the longer fall back option.

I'll mull it over for a few days, it's not the end of the world and doesn't impact on the body above, or the chassis already completed.