You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Mickoo's Commercial Workbench

- Thread starter mickoo

- Start date

P A D

Western Thunderer

Hi Larry,

I think you refer to the flexible slacking pipe on the footplate. In the case of the Duchess tender there are two fixed pipes either side at the top of the raves and running about half the length of the bunker, for watering the coal to keep the dust down. BR tenders had one running across the inner face of the bunker front plate, but I'm sure there were variations. They had slacking pipes on coaling plants as well to reduce dust when filling the tenders.

Cheers,

Peter

I think you refer to the flexible slacking pipe on the footplate. In the case of the Duchess tender there are two fixed pipes either side at the top of the raves and running about half the length of the bunker, for watering the coal to keep the dust down. BR tenders had one running across the inner face of the bunker front plate, but I'm sure there were variations. They had slacking pipes on coaling plants as well to reduce dust when filling the tenders.

Cheers,

Peter

Peter Cross

Western Thunderer

I was alreays amazed how much heat was produced in a wet 20 ton of coal. Bagging up in winter you feel the heat.

mickoo

Western Thunderer

Have wheels, will travel

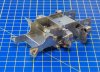

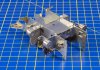

It's worth taking the time to ensure the chassis core is straight and true before adding the rest of the appendages. The reality was it took over five hours to decusp these few parts but it's worth the visuals in the end. Once the frames were built nice and square it was a simply case of adding the horn guides, in this case fully sprung.

The rest of the frames, bogie and trailing truck should not take too long at all. As it stands I cannot see any side control arrangement for the front bogie so I'll graft in a spare set from one of the W1 test etches.

It's worth taking the time to ensure the chassis core is straight and true before adding the rest of the appendages. The reality was it took over five hours to decusp these few parts but it's worth the visuals in the end. Once the frames were built nice and square it was a simply case of adding the horn guides, in this case fully sprung.

The rest of the frames, bogie and trailing truck should not take too long at all. As it stands I cannot see any side control arrangement for the front bogie so I'll graft in a spare set from one of the W1 test etches.

Focalplane

Western Thunderer

Very nice, Mick, but when you say you have sprung the 6 hornblocks, where are the springs? Are they placed over the BA adjustment screws and hidden by the bearings?

Paul

Paul

P A D

Western Thunderer

No they won't lol. There's solder where there needs to be and none where there shouldn't be, it's as simple as that.

I try to do the same but I'm not as good at it as you. I've got an Iroda Solderpro so I'll have to experiment more with that.

Yorkshire Dave

Western Thunderer

Paul, that's correct, the springs are tiny and suffer from projectilus disappearus so they go in near the end, or when the axle box keep plates, and/or, springs are fitted.

Isn't that an automatic customer relations exercise for manufacturers to supply 8 springs in a set of 6 hornblocks rather than 6 (or 3 springs in a pair rather than 2)?

Focalplane

Western Thunderer

I seem to be buying Slaters spare sets too often! And then wait a week for the post to arrive (in France). And all the spares I have are not the ones that disappear.

mickoo

Western Thunderer

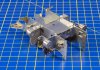

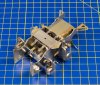

Small progress, front end core structure built up.

Now it's time to add the castings and details to finish it off before fitting to the front of the engine, all of the etch work is prepared so it won't take long to rattle through.

Top view, of note (as mentioned in Pauls thread) are the cylinder fixing screw clearance holes, the instructions advise 2.4 mm but that leaves very little of the screw head to grip the components. The reduced size of 1.9 mm is top left, the instructions will be adjusted in due course.

From below the inside motion plate work is in place, currently there's a big gap between the inside cylinder front and rear walls, this'll need filling as it lets too much daylight into this area and the engine loose some of it's mass appeal at the front end, my personal view only.

Adding the cylinder base will add additional clearance problems as the front bogies are O fine and the frames are scale width and the middle cylinder sits partially down inside the front wheels. The 1:1 cylinder base has a notch in the casting so I'll add that but probably exaggerate it's cut into the cylinders to give the additional clearance.

The Princess Royal has the same feature.

Of additional interest here is the rubbing of the front bogie wheel on the middle cylinder casting. I can't be sure....or recall correctly...but I think there's a sacrificial plate in there held by the clip seen at the top, the plate being there to protect the casting behind. I mentioned this feature recently as real engines don't care if the wheels touch the frames, where as models do. One way around this (which I may well do) is to add a thin Plasticard spacer with a NS rubbing plate outside, like the real thing, we'll see. You can also see the great big clip bolted on to the frames to also stop the bogie lateral play.

The other downside is the front fixing passes through here so I've two choices, move the fixing elsewhere so that the cylinder base is solid, or put a hole in it to allow the screw through, we'll see, neither are perfect and neither will be an eyesore or abomination.

I've already decided to dispense with the bogie side play limiting arm, two reasons, I think a good sprung side control unit will achieve the same result and second it gets in the way of the inside slide bar mounting bracket, you can see the notch cut in the bracket to clear it. The real bracket has a web along the bottom (as do several of the other stretchers down the engine) so I'll add that from some scrap strip metal and refit to the engine ones as well.

The combined cylinder and middle motion bracket can be removed by removing the four screws, but I'm not sure it can once the middle crossheads and piston rods are in place, they'll poke through the rear wall and when lifted impact the front fixing bracket. Need to think around that, I'm not a big fan of removable motion myself, it tends to create more headaches than solving.

MD

Now it's time to add the castings and details to finish it off before fitting to the front of the engine, all of the etch work is prepared so it won't take long to rattle through.

Top view, of note (as mentioned in Pauls thread) are the cylinder fixing screw clearance holes, the instructions advise 2.4 mm but that leaves very little of the screw head to grip the components. The reduced size of 1.9 mm is top left, the instructions will be adjusted in due course.

From below the inside motion plate work is in place, currently there's a big gap between the inside cylinder front and rear walls, this'll need filling as it lets too much daylight into this area and the engine loose some of it's mass appeal at the front end, my personal view only.

Adding the cylinder base will add additional clearance problems as the front bogies are O fine and the frames are scale width and the middle cylinder sits partially down inside the front wheels. The 1:1 cylinder base has a notch in the casting so I'll add that but probably exaggerate it's cut into the cylinders to give the additional clearance.

The Princess Royal has the same feature.

Of additional interest here is the rubbing of the front bogie wheel on the middle cylinder casting. I can't be sure....or recall correctly...but I think there's a sacrificial plate in there held by the clip seen at the top, the plate being there to protect the casting behind. I mentioned this feature recently as real engines don't care if the wheels touch the frames, where as models do. One way around this (which I may well do) is to add a thin Plasticard spacer with a NS rubbing plate outside, like the real thing, we'll see. You can also see the great big clip bolted on to the frames to also stop the bogie lateral play.

The other downside is the front fixing passes through here so I've two choices, move the fixing elsewhere so that the cylinder base is solid, or put a hole in it to allow the screw through, we'll see, neither are perfect and neither will be an eyesore or abomination.

I've already decided to dispense with the bogie side play limiting arm, two reasons, I think a good sprung side control unit will achieve the same result and second it gets in the way of the inside slide bar mounting bracket, you can see the notch cut in the bracket to clear it. The real bracket has a web along the bottom (as do several of the other stretchers down the engine) so I'll add that from some scrap strip metal and refit to the engine ones as well.

The combined cylinder and middle motion bracket can be removed by removing the four screws, but I'm not sure it can once the middle crossheads and piston rods are in place, they'll poke through the rear wall and when lifted impact the front fixing bracket. Need to think around that, I'm not a big fan of removable motion myself, it tends to create more headaches than solving.

MD

Cliff Williams

Western Thunderer

mickoo

Western Thunderer

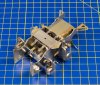

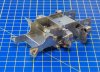

Okay, nearly there, just a few more bits to add on tomorrow and then it'll go onto the main frames.

It's all as per the kit except the inside cylinder base and wheel cutouts, I've not added the cutout arched splasher plate work yet, I'll do that once I'm certain the cutout is large enough.

It's only a couple of pieces of sheet brass but I think it adds a little more visual mass up front, it'll be better once the actual splasher plates go in. I'm also going to leave the rear splashers off as well, I may need to make new ones slightly wider, we'll see. I still need to add the web to the rear inside slidebar bracket and will drill the six small holes for the drain cocks later as well.

I may still have to punch a big hole in the middle for the fixing screw, I'm hoping not too and am currently thinking of some sort of locating slot/lug at the front with only the rear screws to hold the chassis in place. All still very fluid on that point at the moment.

The bogie stretcher is now also beginning to bug me, it's nothing like flat on the real engine and drops down down to sit inside the bogie and is a big light blocker in that area. I may whizz up a simple pseudo shaped one with a hollow in the middle to take the spring, we'll see.

The front end fixes to the main frames with four pins (once the frame overlays are fitted), currently it's just roughly fitted with two wire rods.

Onward.

It's all as per the kit except the inside cylinder base and wheel cutouts, I've not added the cutout arched splasher plate work yet, I'll do that once I'm certain the cutout is large enough.

It's only a couple of pieces of sheet brass but I think it adds a little more visual mass up front, it'll be better once the actual splasher plates go in. I'm also going to leave the rear splashers off as well, I may need to make new ones slightly wider, we'll see. I still need to add the web to the rear inside slidebar bracket and will drill the six small holes for the drain cocks later as well.

I may still have to punch a big hole in the middle for the fixing screw, I'm hoping not too and am currently thinking of some sort of locating slot/lug at the front with only the rear screws to hold the chassis in place. All still very fluid on that point at the moment.

The bogie stretcher is now also beginning to bug me, it's nothing like flat on the real engine and drops down down to sit inside the bogie and is a big light blocker in that area. I may whizz up a simple pseudo shaped one with a hollow in the middle to take the spring, we'll see.

The front end fixes to the main frames with four pins (once the frame overlays are fitted), currently it's just roughly fitted with two wire rods.

Onward.

Focalplane

Western Thunderer

So, you were busy while I skived off watching rugby yesterday! As I now have the 20 BA taps I have no excuse to catch up and your excellent work can only serve as encouragement. Onward, indeed!

Paul

Paul

P A D

Western Thunderer

The slide bars are an additional kit available from Finney7, all I added was the base to the middle cylinder bottom.

All of the soldering is done from inside the joints and so far almost all with a blow torch.

I must get it into my head that Finney 7 are a supplier of castings etc and not just a kit supplier.

Focalplane

Western Thunderer

10BA, sorry to mislead. Paul