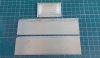

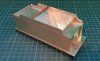

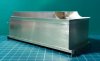

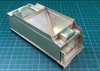

As mentioned earlier, the instructions suggest fitting the frames, then adding the 18 parts each side for the springs and axleboxes. They also suggest making up and adding the steps after the frames are fitted. However, it is far easier to fit the parts to the frames in the flat and also fit the steps to the valances before fitting the frames. Here are the completed frames and steps ready for fitting.

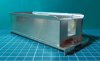

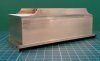

Here are the parts after fitting to the tender. There's a half etch groove to locate the frames and all soldering was done on the inside.

I hope having the frame detail in place does not cause undue problems during painting, but with so many parts to fit, it would not be practical to leave them off until after painting.

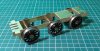

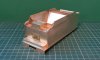

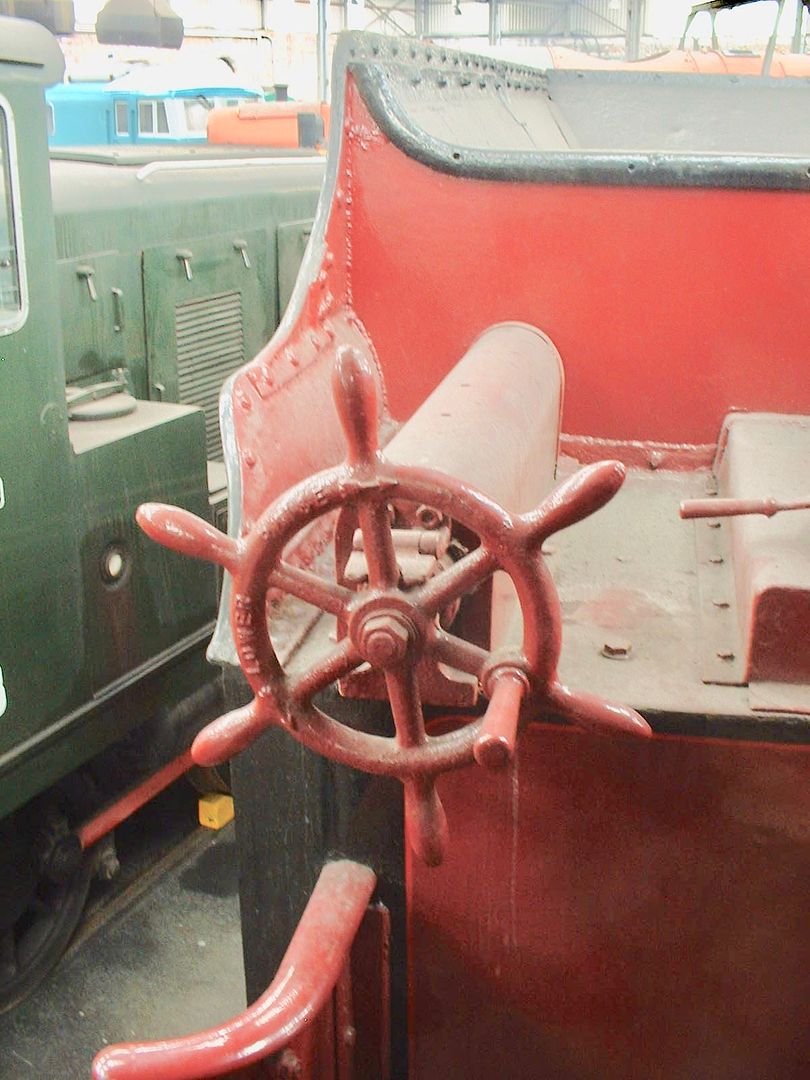

And a shot on the chassis.

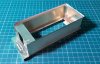

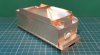

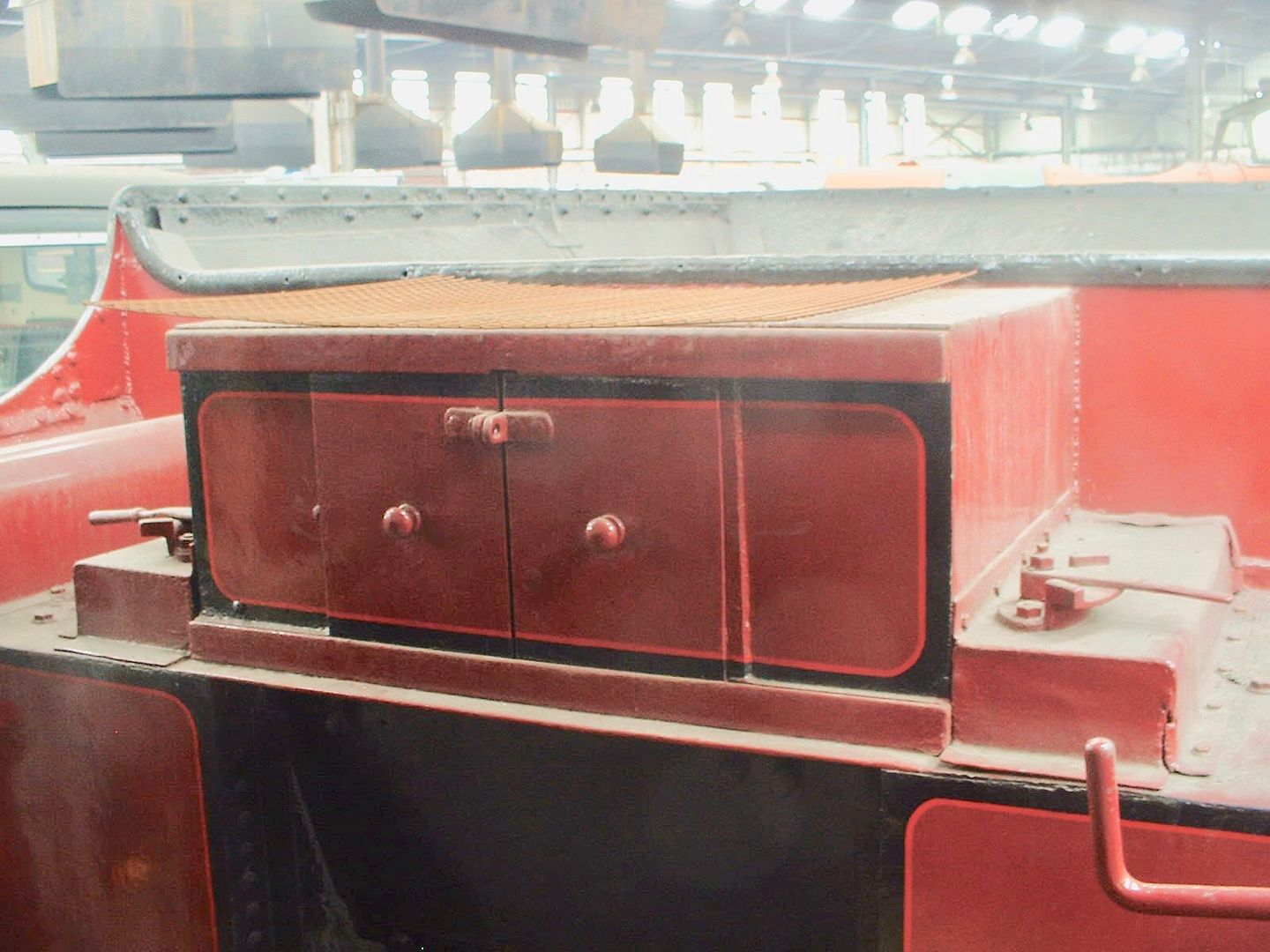

I've replaced the filler/water scoop casing handles on the lids and added tank the lifting brackets. The instructions are a bit vague as to the position of the brackets so if anyone knows better, please let me know. The filler/water scoop casing were epoxied in place and some cleaning up of oozed out resin is still to do.

I made a start on the brake gear so hopefully that will be done later today.

Cheers,

Peter