Thanks chaps.

Or it could be that as Tim Watson mentioned, they broke down a lot so the boxes were full of spares and spanners!

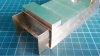

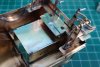

Here's a view under the frame sub section showing the added piece of waste fret to provide greater support to the vacuum brake pipe when glued in after painting.

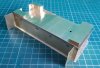

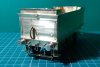

Moving on to the coping, after curving the two sides and rear using bending bars, the rear was added first. To facilitate fitting the parts in the correct position, two simple jigs are provided. They are tacked soldered to either end of the tank plates and the coping then slots into place and is set at the correct height. This is then tack soldered and the jigs removed for use with the next piece.

Here the left hand coping has been tacked in place before removing the jigs and tack soldering them to the other side.

Finally, the three parts are fully soldered along their lengths, the corners infilled with solder and all is then scraped and scratched brushed to clean up.

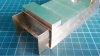

And from t'other side.

And from the rear. The remaining lamp iron and bracket can then be added to the top edge of the coping.

Here's the tank filler after fitting in place. It's a mix of etchings for the base plate and lid, and white metal for the tube.

At the front end the footplate furniture has been added along with the coal space door. For the door, two optional parts are supplied. One for the closed position and one for the open, which is fitted below the ledge. The open door just has the rivets without the straps and I laminated the two before fitting, so that the inner face did not show the dimples from the strap rivets.

And a view from the inside.

On the frame subsection the intermediate dummy buffers have been added.

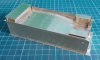

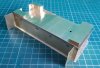

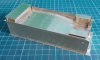

Here are the three sub sections.

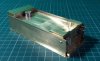

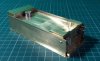

And some views after screwing it all together.

The grab rails and vacuum brake pipe are a firm sliding fit in the locating holes and after positioning can be super glued on the inside to secure without risk of damage to the paint.

At the front the handrails are just slotted into place for the photo.

That's it until I return from holiday at the end of the month when one more session should see it ready for the painter.

Cheers,

Peter