LarryG

Western Thunderer

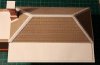

I described modelling the station masters house and waiting room at Carrog station (Dee Valley) in workbench thread, but it got unwieldy and was slow opening up. So I decided to put this in the GWR Action section seeing as the brick waiting room was something of a house-style in parts of the GWR.

The first move was to photograph the building square-on with as little perspective tailoff as possible. Having measured the length of the building (29' 6"), the photo was then printed off to 7mm scale, which was then used as a scale drawing....

The lavatory wall is 84" long, then 41" to the first window on the left, 23" for each window with 13" in between them. 36" to the door. 40" door width and then 60" to the end of the building. The height of the waiting room from platform is 10' 3".

The lavatory end wall measurements are: 56" to the doorway. 36" wide doorway, 18" to end on wall. The canopy width is 66".

The opposite end of the building is partially below ground level due to the path down to the Down platform. Therefore only 92" of the end wall is visible above ground level and only 72" of the wall where it is adjacent to the field. The building is set back 11' from the platform edge.

The first move was to photograph the building square-on with as little perspective tailoff as possible. Having measured the length of the building (29' 6"), the photo was then printed off to 7mm scale, which was then used as a scale drawing....

The lavatory wall is 84" long, then 41" to the first window on the left, 23" for each window with 13" in between them. 36" to the door. 40" door width and then 60" to the end of the building. The height of the waiting room from platform is 10' 3".

The lavatory end wall measurements are: 56" to the doorway. 36" wide doorway, 18" to end on wall. The canopy width is 66".

The opposite end of the building is partially below ground level due to the path down to the Down platform. Therefore only 92" of the end wall is visible above ground level and only 72" of the wall where it is adjacent to the field. The building is set back 11' from the platform edge.

Last edited: