Brian McKenzie

Western Thunderer

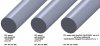

Another 'variable' for AutoCAD users to experiment with. 'FACETRATIO', in addition to 'FACETRES', may further help smooth ugly faceting when creating STL files for 3D printing.

The default setting of the system variable FACETRES is 0.5

Change this to 10 - by entering FACETRES on the command line, and then type 10.

The variable 'FACETRATIO' controls the aspect ratio of facets on rounded 3D bodies. The default setting is 0. Change this to 1, after entering FACETRATIO on the command line.

As can be seen above, the file size grows massively when FACETRATIO, now changed to 1, is used in addition to the FACETRES variable when set at 10. I couldn't see any visual improvement when trying it with FACETRES left at its default setting of 0.5 (as for the coarsely faceted cylinder shape above left), but the file size did increase from 5 to 26kb.

Whether tinkering with FACETRATIO translates into improved 3D prints remains to be seen. It doesn't, see next message.

(Note, to see these changes within exported STL files, it may be necessary to view with 3rd party software.)

-Brian McK.

The default setting of the system variable FACETRES is 0.5

Change this to 10 - by entering FACETRES on the command line, and then type 10.

The variable 'FACETRATIO' controls the aspect ratio of facets on rounded 3D bodies. The default setting is 0. Change this to 1, after entering FACETRATIO on the command line.

As can be seen above, the file size grows massively when FACETRATIO, now changed to 1, is used in addition to the FACETRES variable when set at 10. I couldn't see any visual improvement when trying it with FACETRES left at its default setting of 0.5 (as for the coarsely faceted cylinder shape above left), but the file size did increase from 5 to 26kb.

Whether tinkering with FACETRATIO translates into improved 3D prints remains to be seen. It doesn't, see next message.

(Note, to see these changes within exported STL files, it may be necessary to view with 3rd party software.)

-Brian McK.

Last edited:

.

.