jamiepage

Western Thunderer

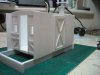

Inspired by Steve Cook's G3 brake van project, a start has been made on a scratchbuilt G3 SM&AR brake van in plasticard.

Working sketch has been made from a copy of the original Metropolitan RC&WCo. drawings and the first components started.

Use was made of the milling machine and indexing to get the floor and partition/end blanks nice and square.

These blanks were built up from two layers each of .100 thou. card (external framing will provide a third layer) so quite chunky, and squareness from the milling process will be useful to keep it all straight.

The door opening was recessed as the prototype.

Some internal corners need squaring off .

Headstock and solebar blanks built up to size from various sections.

Working sketch has been made from a copy of the original Metropolitan RC&WCo. drawings and the first components started.

Use was made of the milling machine and indexing to get the floor and partition/end blanks nice and square.

These blanks were built up from two layers each of .100 thou. card (external framing will provide a third layer) so quite chunky, and squareness from the milling process will be useful to keep it all straight.

The door opening was recessed as the prototype.

Some internal corners need squaring off .

Headstock and solebar blanks built up to size from various sections.

Fully understand that decision Jamie (thanks for posting the pic to show how it all works), replicating that mechanism (or even trying to) would be a little excessive, even in G3

Fully understand that decision Jamie (thanks for posting the pic to show how it all works), replicating that mechanism (or even trying to) would be a little excessive, even in G3